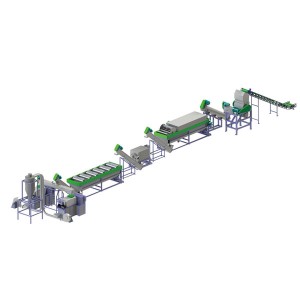

SJ type pelletizing machine for PP PE rigid plastics and squeezed plastics

Video:

General information:

SJ pelletizing machine is mainly for the rigid plastics recycling, such as the crushed or regrind PE, PP, PS, ABS, PC,PA6 etc. Those rigid plastics comes from household appliances, HDPE drums for oil and fuel, HDPE milk bottles, detergent and shampoo bottles, etc. It can also recycle the washed and squeesed dry PE, PP films and soft plastics.

Application:

l Crushed or regrind PE, PP, PS, ABS, PC,PA6

l Squeezed washed PP and PE films.

Features:

1.Two times filtering will guarantee the pellets quality. The filtering mesh size the first stage can use 60mesh. The second stage filtering mesh will be 80-100mesh.

2.Great vacuum degassing system. We use the watering vacuum pump in the pelletizing line. The exhausted gas extract from the extruder and goes into water cylinder for filtering.

3.The screw design is specialized to specific materials.

4.The heaters we used in the barrel is best and reliable in China with long service time.

5.Pelletizing method is optional. The watering pelletizing is suitable for PP and PE films, while for the strand pelletizing it can be used in PP PE and PC and ABS and PA. Also the underwater pelletizing will be universal. All pelletizing method will be easy to maintain and long service time.

6.Good motor brands and qualified high torque gearbox. We use the China best brand motors, Dazhong,and the WEG with UL certification, ABB motors, and Siemens motors optional. Electric parts use the the international brand Schneider or Siemens. Temperature control OMRON. Siemens PLC control is available. Good electric protection method in the machine.

7.Nice design for the safety and usage in plant. We have strict quality control.

We have been in this plastic pelletiizng field for more than 16 years exporting to more than 80 countries all over the world. With much experience and technology workers to solve your plastic recycling machine.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.