China Wholesale Battery Equipment Factory – Aluminum acid battery – Purui

China Wholesale Battery Equipment Factory – Aluminum acid battery – Purui Detail:

video

Introduce

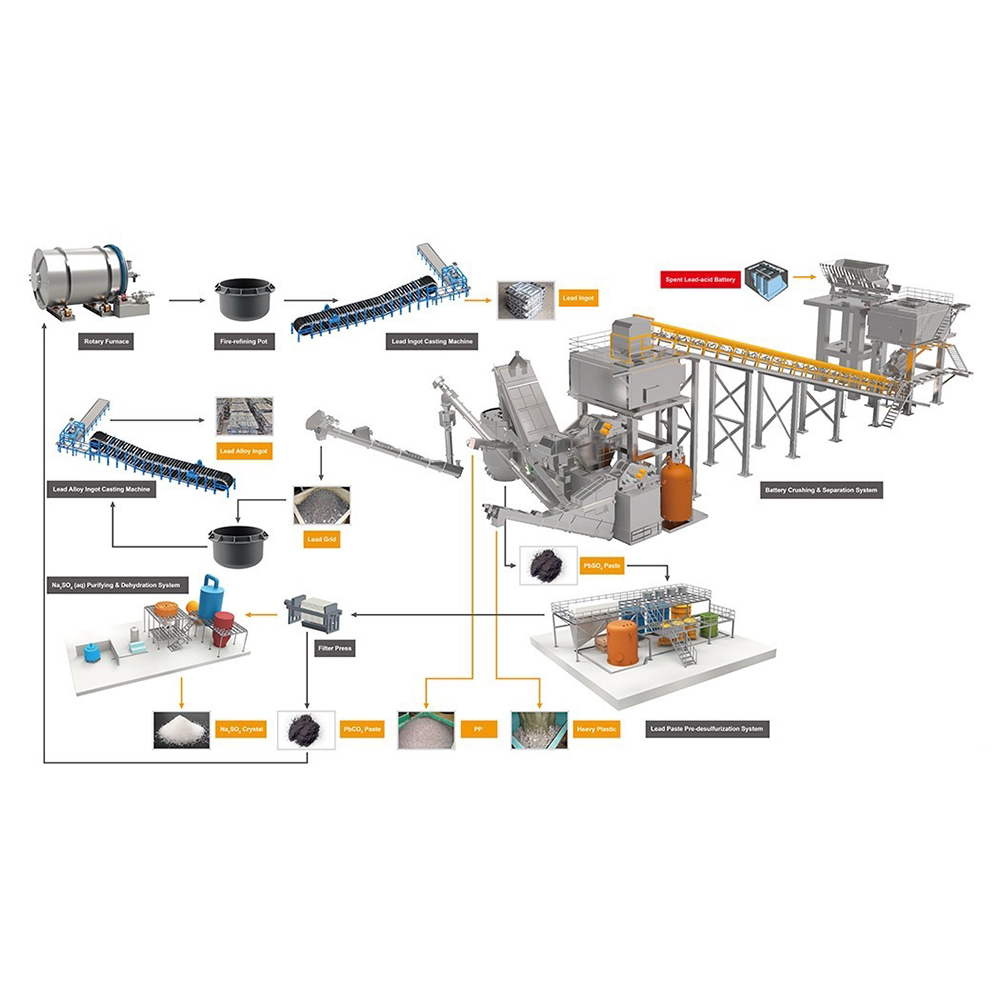

The working principle of the waste lead storage battery crushing and separating system is that the storage battery is crushed by a crusher, the crushed fragments are cleaned by a vibrating screen, lead mud is washed away, the cleaned fragments enter a hydraulic separator and are separated by utilizing the characteristics of different specific gravity of materials, and the separated battery plastic fragments and a lead grid pass through screw conveyor output systems from different outlets of the hydraulic separator.

The specific process is to break the waste lead-acid battery to pieces less than 100mm through the knife edge on the hammer head of the crusher and then enter the vibrating screen, in which a plurality of water spray nozzles are arranged, and the materials are fully cleaned under the double action of water power and vibration.

Lead mud in the battery debris is flushed into the lead mud precipitator through the mesh of the sieve plate, and flocculating agent in an appropriate proportion is added into the lead mud precipitator to promote flocculation and sedimentation of the lead mud, so that a scraper in the lead mud precipitator is convenient to convey to a lead mud stirring tank, then lead mud in the tank is conveyed to a filter press through a lead mud conveying pump, and lead paste is formed after pressure filtration, and the lead paste can be conveyed to a pre-desulfurization system for continuous treatment.

At the same time, polypropylene, heavy plastic and lead grid separated after vibration cleaning are sent to the hydraulic separator by the vibrating screen. Due to the different specific gravity of the materials, the above three materials are sent out from the upper, middle and lower outlets respectively after being separated by the hydraulic separator. In order to ensure the thorough cleaning and separation of various materials, the system carries out secondary cleaning and separation of materials, thus ensuring the cleaning and separation effects of various materials.

The system adopts full-screen monitoring, automatic control and high degree of automation. The main equipment adopts 316L stainless steel with good corrosion resistance. Acid liquor in the whole equipment forms an integral internal circulation system. In addition, acid mist dust removalpipelines are connected to the top of each main equipment in a toxic way, acid mist generated in the production process is pumped to an acid mist cleaning filter for cleaning and filtering, and is discharged into the atmosphere after reaching the standard through detection, thereby preventing air pollution and meeting environmental protection requirements.

breaking and separation unit

|

Serial numb er |

Device name | Specification model | Quantit y Table/s et | Main material | Remarks |

| 1.1 | Vibrating feeder | ZG-1000-3000 | 1 | Q235-ALining 316L | P=2×3KW |

|

Attached: Weighing Device |

10T sensor | 4 | Hunan Jiangye | Changsha titanium alloy | |

| 1.2 | Belt conveyor | JYPF05DB.16 | 1 | Leg 304/Q235idler 304 Belt Fluorine rubber | Belt width 800;P=4KW, fully enclosed |

| 1.3 | Magnetic iron remover | RCDD-10 | 1 | Q235-A | P=15KW |

| 1.4 | Crusher soundproof room | JYPF05DB.19 | 1 | Combinati on | |

| 1.5 | Crusher | JYPF05DB.1 | 1 | 316L/304 | 90KW, 20hammers, 4 air springs |

| 1.6 | Dilute oil lubrication station | XYZ-6 | 1 | Q235A | 2×0.75K W |

| 1.7 | Primary vibrating screen | JYPF05DB.2 | 1 | Liquid contact portion 316L,reinforcing ribs, legs, | Sieve plate 800x 800mm, quantity 3, p = 2 x |

| 1.8 | Diaphragm | JYPF05DB.3 | 1 | Liquid | |

| filter | contact | ||||

| portion | |||||

| 316L, | |||||

| reinforcing | |||||

| ribs, legs, | |||||

| etc. 304 | |||||

| 1.9 | Primary | JYPF05DB.5 | 1 | Liquid | Blade |

| lead grid | contact | diameter | |||

| screw | portion | Φ 280× | |||

| conveyor | 316L, | 10. shaft | |||

| reinforcing | diameter | ||||

| ribs, legs, | Φ 127× | ||||

| etc. 304 | 15, | ||||

| P=7.5KW | |||||

| 1.10 | Secondary | JYPF05DB.6 | 1 | Liquid | Blade |

| lead grid | contact | diameter | |||

| screw | portion | Φ 280× | |||

| conveyor | 316L, | 10. shaft | |||

| reinforcing | diameter | ||||

| ribs, legs, | Φ 127× | ||||

| etc. 304 | 15, | ||||

| P=7.5KW | |||||

| 1.11 | Lead mud | JYPF05DB.10 | 1 | Liquid | |

| settling tank | contact | ||||

| portion | |||||

| 316L, | |||||

| reinforcing | |||||

| ribs, legs, | |||||

| etc. 304 | |||||

| 1.12 | Lead mud | JYPF05DB.11 | 1 | Liquid | P=7.5KW |

| mixing tank | contact | V=10m3 | |||

| portion | |||||

| 316L, | |||||

| reinforcing | |||||

| ribs, legs, | |||||

| etc. 304 | |||||

| 1.13 | Filtrate tank | JYPF05DB.12 | 1 | PP | V=10m3 |

| 1.14 | Hydrodyna mic separator | JYPF05DB.15 | 1 | 316L | ||||

| 1.15 | Horizontal screw conveyor | JYPF05DB.22 | 1 | Liquid contact portion 316L,reinforcing ribs, legs, etc. 304 | Blade diameter Φ 275× 8diameter of axle φ108×8 P=5.5KW | |||

| 1.16 | Neutralizatio n tank | JYPF05DB.23 | 1 | Liquid contact portion 316L,reinforcing ribs, legs, etc. 304 | P=11KW | |||

| 1.17 | buffer tank | JYPF05DB.24 | 1 | Liquid contact portion 316L,reinforcing ribs, legs, etc. 304 | P=3KW | |||

| 1.18 | Acid filter | JYPF.0TB702 | 2 | 316L |

One for standby and one for use |

|||

| 1.19 | cooling water tank | JYPF.0TB1102 | 1 | PP | ||||

| Second, the acid mist dust removal part | ||||||||

| 2.1 | Spray purification | JYPF05DB.31 | Hunan Jiangye | 1 | PP | φ2600*60 00 | ||

| 2.2 | Induced draft fan | 4-52-B | 1 | Glass fibre reinforced plastics | Fan motor P=22KW | ||||

| 2.3 | liusuan pump | 60FS-35 | 1 | Plastic lining | |||||

| 2.4 | Smoke exhaust window | JYPF | 1 | PP | H≤25m | ||||

| Three, all kinds of acid pump | |||||||||

| 3.1 | Water separation pump | Q=60m³/h, H=11m | 1 | Overcurren t section 316L | Xin Jiuyang | ||||

| 3.2 | Acid circulating pump | Q=25m³/h, H=50m | 1 | Overcurren t section 316L | Xin Jiuyang | ||||

| 3.3 | Filtrate transfer pump | Q=30m³/h, H=30m | 2 | Overcurren t section 316L | Xin Jiuyang | ||||

| 3.4 | Lead mud transfer pump | Q=25m³/h, H=58m | 3 | Overcurren t section CD4MCu | Xin Jiuyang | ||||

| 3.5 | Submerged sewage pump | Q=10m³/h, H=20m | 1 | Overcurren t section 316L | Xin Jiuyang | ||||

| 3.6 | cooling water pump | Q=4m³/h, H=52m | 2 | The overcurrent section 304 | Xin Jiuyang | ||||

| Four, stairs, pipeline platform | |||||||||

| 4.1 |

All kinds of connecting pipes |

1 | |||||||

| A. acid and lead mud pipelines | 316L、PP | Including instrumen ts and meters Automatic manual valve | ||||||

| B. acid mist pipeline | PPR/PP | |||||||

| C.pneumatic and cooling water piping | 304 | Including instrumen ts and meters Automatic manual valve | ||||||

| 4.2 | Platforms, stairs, railings, Some equipment supports | 1 | Painted Q235B | |||||

| Five, electrical control system | ||||||||

| 5.1 | GCK power control cabinet | Width × Depth× Height 800×1000×2200 | 4. | Combinati on | ||||

| 5.2 | programma ble logic controller | Width × Depth× Height 1600×800×2200 | 1 | Combinati on | Siemens 1200Series | |||

| 5.3 | IPC | IPC- | 1 set | Yanhua | ||||

| 610L/FSP250-70PSU/EBC- MB06G2/I5- 2400/8G/SSD240G | |||||||

| 5.4 | Wire and cable | 1 batch | Gold Cup, Constant Flying (copper core national standard cable) | ||||

| 5.5 | Sensor | 1 batch | Changsha titanium alloy | ||||

| 5.6 | Cable tray | 1 batch | Spray plastic | ||||

| 5.7 | Video surveillance system | 1 set | Combinati on | ||||

| 5.7.1 |

Liquid crystal display |

46 inches | 4 yuan | Samsung or equivalent | |||

| 5.7.2 | Desktop managemen t computer | Dual-core G3250,4G,21.5 inches | 1 set | Dell or equivalent | |||

| 5.7.3 | Hard disk video recorder | DS-7716N-I4 | 1 set | Haikang or equivalent brand | |||

| Six, filter pressing part | |||||||

| 6.1 | plate and frame filter press | 50m² | 3 | Jingjin | |||

| 6.2 | Squeeze pump | Q=10m³/h, H=120m | 2 | The overcurre nt section 304 | Xin Jiuyang |

| 6.3 | Squeeze water tank | JYPF.0TB1401 | 1 | PP | |

| Seven, after-sales service | |||||

| 7.1 | Production training | ||||

| 7.2 | Operation and maintenanc e training | ||||

| 7.3 | Installation and commission ing | ||||

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for China Wholesale Battery Equipment Factory – Aluminum acid battery – Purui , The product will supply to all over the world, such as: Melbourne, Vietnam, Uruguay, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

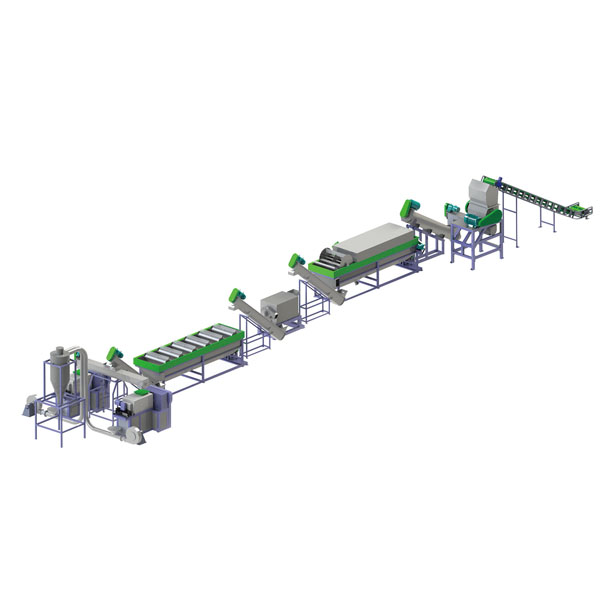

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.