China Wholesale EPS Plastic Mill Suppliers – PET bottle flakes washing line – Purui

China Wholesale EPS Plastic Mill Suppliers – PET bottle flakes washing line – Purui Detail:

Product Video:

1000 kg/h HDPE bottles washing line layout

1.bale opener

2.Belt conveyer

3.Drum screen

4. Belt conveyer

5. Label remover

6. Pre-washer

7.Intelligent optical sorting system

8.Manual sorting system

9.Crusher

10. Hot washer

11.Screw loader

12.Floating washer

13.High speed friction washer

14.Dewatering

15.Round floating washer

16.Floating washer

17.Dewatering

18.Pipe drying

19.Bottle label separator

20.Compacting packing

Features equipment:

1.Bale opener

Newly design PET bottles bales opener. Four shaft effectively open the bales and convey the separated bottles into the belt.

2.Label remover

Effectively remove the labels on the pressed bottles 99% and labels on the round bottles 90%.

3.Dewatering machine

It can remove water and sand to reach moisture 1%.

4.Bottle flakes labels separator

Effectively remove the crushed labels mixed in the bottles flakes.

The washing line consumption:

| Items | Average consumption |

| Electricity(kwh) | 170 |

| Steam (kg) | 510 |

| Washing detergent (kg/ton) | 5 |

| Water | 2 |

quality and specification:

| Capacity(kg/h) | Power installed(kW) | Required space(M2) | Labour | Steam requirement(kg/h) | Water consumption(M3/h) |

| 1000 | 490 | 730 | 5 | 510 | 2.1 |

| 2000 | 680 | 880 | 6 | 790 | 2.9 |

| 3000 | 890 | 1020 | 7 | 1010 | 3.8 |

flakes quality reference table:

| Moisture content | <0.9-1% |

| PVC | <49ppmm |

| Glue | <10.5ppm |

| PP/PE | <19ppm |

| Metal | <18ppm |

| Label | <19ppm |

| Variegated tablets | <28ppm |

| PH | Neutral |

| Total impurity | <100ppm |

| Flakes size | 12,14mm |

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for China Wholesale EPS Plastic Mill Suppliers – PET bottle flakes washing line – Purui , The product will supply to all over the world, such as: Thailand, Buenos Aires, Korea, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

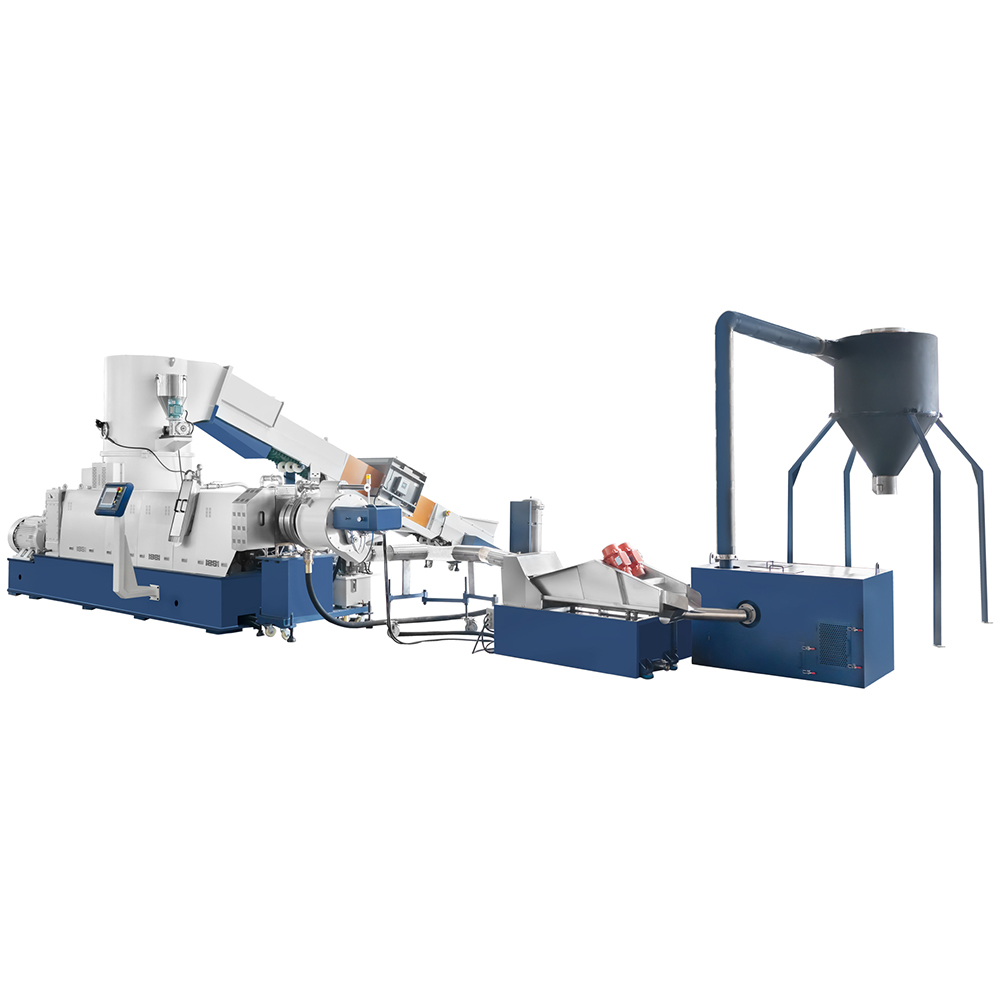

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!