China Wholesale High Output Plastic Sheet Extruder Pricelist – The infrared preheating devolatilization system – Purui

China Wholesale High Output Plastic Sheet Extruder Pricelist – The infrared preheating devolatilization system – Purui Detail:

The infrared preheating devolatilization system adopts infrared radiation of the specified wavelength to heat the plastic raw material, such as the PA6/PA66, PBT, PC, PLA, PET and PETG,PP, PE etc.

After reaching the preset temperature, the materials will go to the vacuum module. The release of the colatile components in the cacuum environment is accelerated and desalination drying is cassried out.

Technical features:

- Simple structure,easy to clean and quickly change-over

- Degassing,drying process for continuous processing

- Vertical desing of the system to minimize the occupation area

- High efficiency and energy saving, 60% evergy saving compared with electric heating process.

- After treatment VOC content: < 10ppm

- After treatment moisture content:< 150ppm

- Processing capacity:1-3 t/h

- Raw material could be suitable: PA6/PA66, PBT, PC, PLA, PET and PETG,PP, PE etc.

The machine could be used in the pelletizing raw material pretreatment (drying and devolatilization)and after pelletizing raw material drying and devolatilization.

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for China Wholesale High Output Plastic Sheet Extruder Pricelist – The infrared preheating devolatilization system – Purui , The product will supply to all over the world, such as: Iraq, Austria, The Swiss, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

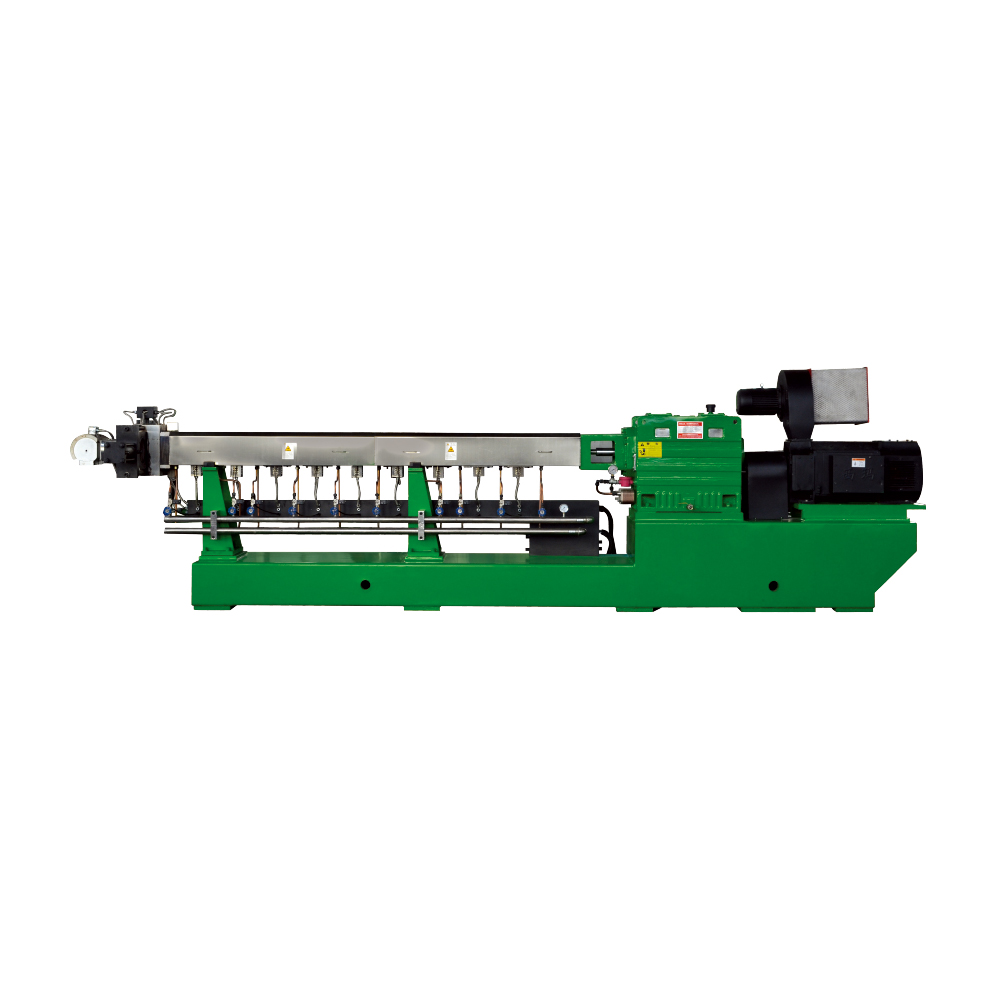

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!