China Wholesale Plastic Film Crusher Pricelist – PET fiber fabrics pelletizing and recycling machine – Purui

China Wholesale Plastic Film Crusher Pricelist – PET fiber fabrics pelletizing and recycling machine – Purui Detail:

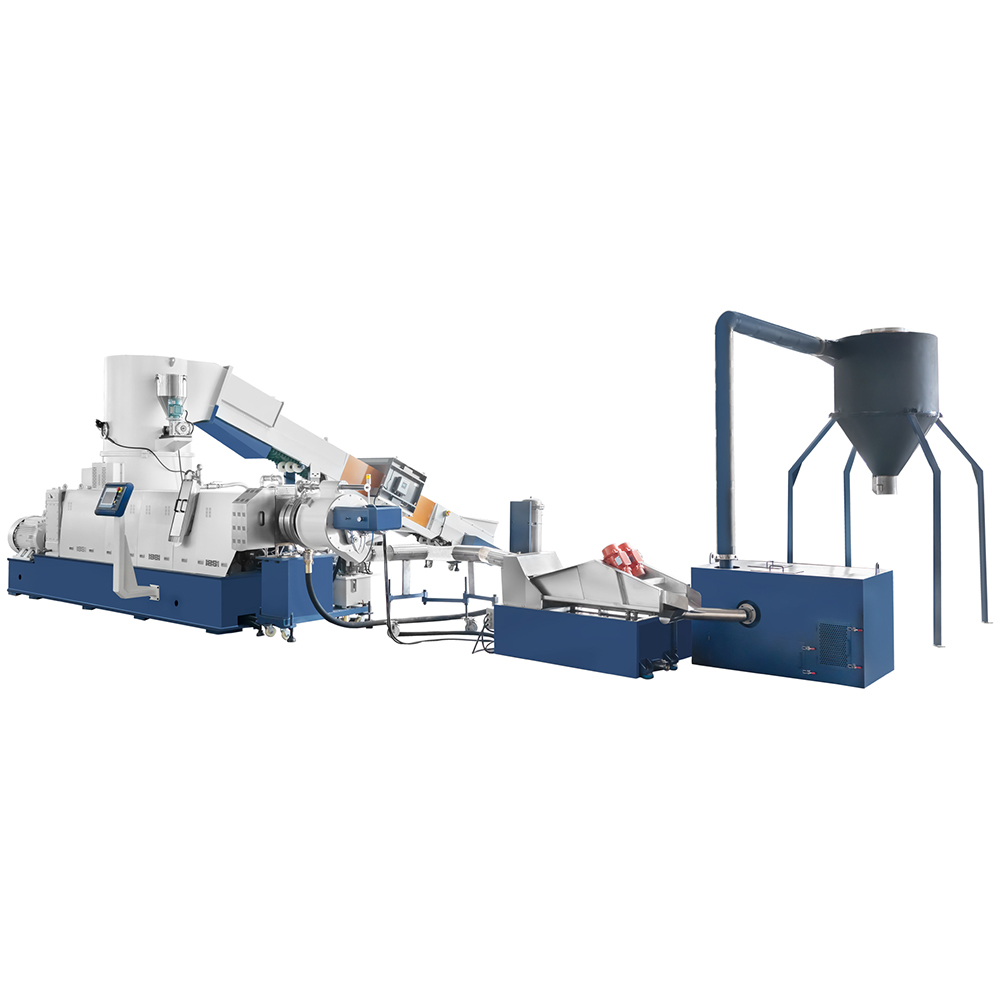

PET fiber fabrics pelletizing and recycling machine

It can recycle the most of the soft plastics and some rigid plastics. The soft material contains wholes rolls and crushed PET fibers and films, PET fabrics, LLDPE, LDPE,HDPE,PP,BOPP,CPP from post industrial or post consumer.

Considering the materials characteristics, for some post industrial material we may prefer the single stages pelletizing system. For example the the BOPP films, PET fibers from water jet weaving selvedges, POY discards and DTY discards etc. Considering the regrind pellets will be used for making the new films or fibers, we improve the filtering system. Finally we add two filters on the single screw. In the middel we add one melt pump to increase melt pressure ensure the melted raw material get into the second filter for fine filtering. It will not only increase the pellets quality but also increase the pellets quality.

Apart from the filtering system, we make some improvement on the cutter compactor to add one dehumifying system, it will largely decrease the moisture content of the raw materials.

Finally we will have the under water strand pelletizing to make the strand easy to feed into the pelletizer. It will save the manual work comparing the dry strand pelletizing.

|

Model |

ML85 |

ML100 |

ML130 |

ML160 |

ML180 |

|

Output(kg/h) |

120-200 |

200-400 |

400-650 |

600-1000 |

800-1200 |

|

Model |

ML85B |

ML100B |

ML130B |

ML160B |

ML180B |

|

Output(kg/h) |

200-350 |

400-550 |

600-800 |

800-1200 |

1000-1500 |

We have been in the plastic recycling machine for more than 15 years. Exporting to more than 70 countries, with good after sale service and reputation. We will continue to serve our customers and offer the best quality machines.

For any enquiry, please contact us freely.

Contact person:Aileen.he@puruien.com

Email: aileen.he@puruien.com

Mobile:0086 15602292676(whatsapp and wechat)

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for China Wholesale Plastic Film Crusher Pricelist – PET fiber fabrics pelletizing and recycling machine – Purui , The product will supply to all over the world, such as: Honduras, St. Petersburg, Angola, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.