China Wholesale Plastic Mini Extruder Suppliers – TSSK series is Co-rotating double/Twin screw extruder – Purui

China Wholesale Plastic Mini Extruder Suppliers – TSSK series is Co-rotating double/Twin screw extruder – Purui Detail:

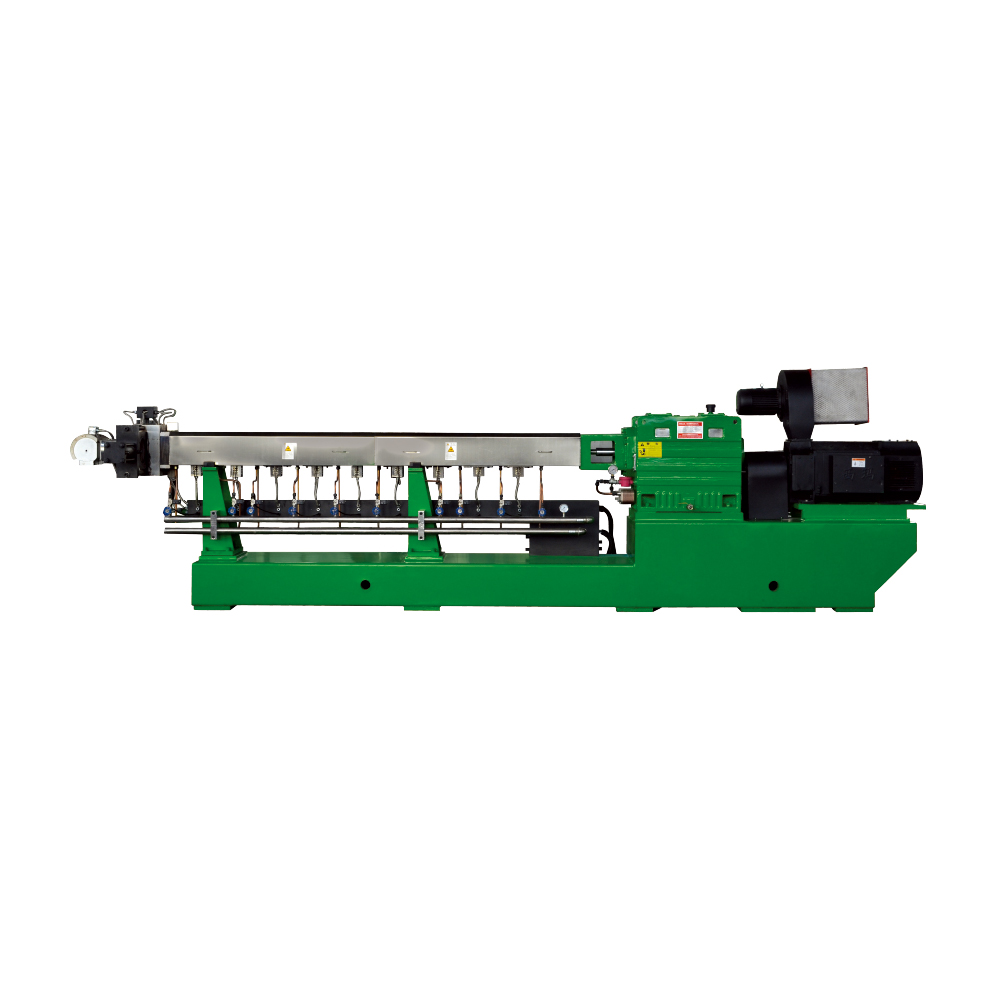

TSSK series is Co-rotating double/Twin screw extruder

More powerful gearbox, more precise screw elements endow TSSK more flexible processing range and wider operation window. We also provide individual solution according to customized requirements. Variety of modular screw elements, barrels, melt filtration and pelletizing system will get the most out of your investment.

Technical characteristics:

High torque: Carrying capacity factor of gearbox>=13

High precision:Run-out accuracy of the output-shaft keep constant,which guarantee small screw clearance

High service life: Designed service life of gearbox is 72000hrs

High speed: Max. 1800rpm

High quality: small clearance reduce material leakage and back-flow, residence time in barrels and excessive shear.

High efficiency: Output is 2-3 times larger than the same size extruder from other domestic manufacturers.

Convenient operation: PLC touch screen with clear operation interface, simple and convenient system operation, integrate the auxiliary control on interface.

Diversity of processing materials: wide speed range can meet kinds of producing different materials, including Crystalline materials, organic dye products, pull film products.

Application:

Filling modification: caco3/talcum powder/Tio2/other inorganic filler

filling modification are used in injection, blow-moulding, film(One layer or Multiple layer), sheet and tapes applications

Reinforce modification: long or short glass fiber/carbon fiber

Preparation of master batch: carbon black master-batch/color master batch/other special functions master batch

Three types of Color masterbatch :

1)Mono color masterbatch or SPC (single pigment concentrate): polymer compounding with one single pigment and mostly without the wax and additive

2) Tailor-Made masterbatch or Custom coloring: mixing different Mono color masterbatch pellets to get the color the customer wants

3) Customized masterbatch: mix polymer and several pigment and additives

Blending modification: thermoplastic material/Elastomer

Cable material: PVC cable material/Zero halogen cable material/special cable material

Technical parameter:

| model | TSSK-20 | TSSK-30 | TSSK-35 | TSSK-50 | TSSK-65 | TSSK-72 | TSSK-92 |

| Screw diameter(mm ) |

21.7 |

30 |

35.6 |

50.5 |

62.4 |

71.2 |

91 |

| Rotary speed(RPM) |

600 |

400 |

400/600 |

400/500 |

400/500 |

400/500 |

400/500 |

| Motor power(Kw) |

4 |

11 |

11/45 |

37/45 |

55/75 |

90/110 |

220/250 |

| L/D |

32-40 |

28-48 |

32-48 |

32-48 |

32-48 |

32-48 |

32-40 |

| Capacity (Kg/H) |

2-10 |

5-30 |

10-80 |

20-150 |

100-300 |

300-600 |

600-1000 |

Product detail pictures:

Related Product Guide:

Sticking towards the principle of "Super High-quality, Satisfactory service" ,We've been striving to become a superb business partner of you for China Wholesale Plastic Mini Extruder Suppliers – TSSK series is Co-rotating double/Twin screw extruder – Purui , The product will supply to all over the world, such as: Slovenia, Zimbabwe, Barbados, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.