China Wholesale Plastic Pelletizing Machine Factory Factories – Two stages plastics Film and fibers and bags Pelletizing machine – Purui

China Wholesale Plastic Pelletizing Machine Factory Factories – Two stages plastics Film and fibers and bags Pelletizing machine – Purui Detail:

Product Video:

Processing Material Pictures:

Processing Material:

HDPE, LDPE, LLDPE, PP, such like films, bags, flakes, film rollers, stretch film, shrink film, multi-layer film, T-shirt bag cut-offs

Foamed PE, EPS and XPS: rolls, bag, sheet, food container, fruit net , cover

Textile: PP fiber, raffia, silk, yarn, woven bag, jumbo bag

Features:

This compactor integrated pelletizing system benefits recycled material without pre-cutting

Compacting get equipped with cutter valves, which used for control material feeding speed

Vacuum system to exhaust water or gas at large extent

Excellent hydraulic screen filter with stable pressure for non-stop, no-leaking

Power saving with high output (0.28kwh/kg)

General working process:

1.Belt conveyor transfer material into shredding compactor.

2.The interlock control system between belt convey to and shredding compactor ensure balance feeding without melted compactor.

3.At the bottom of shredding compactor, there is one cutter board. with centrifugal force, recycled material get pre-cut by inside rotary cutters and stationary cutters.

4.After that, material goes into degassing screw from side of compactor.

5.With screw heating, plastic becomes semi-plastification material.

6.And then, semi-plastic material get cut into pellets.

Main Technical Parameter:

| Model | ML75 | ML85/SJ90 | ML100/SJ120 | ML130/SJ140 | ML160/SJ180 | ML180/SJ200 |

| Screw diameter(mm) | 75 | First stage 85Second stage 90 | First stage 100Second stage 120 | First stage:130Second stage:140 | First stage:160Second stage:180 | First stage:180Second stage:200 |

| L/D | First stage: 26 to 37Second stage:10to 15 | |||||

| Output(kg/h) | 100-150 | 200-350 | 400 to 550 | 600 to 800 | 800 to 1000 | 1000-1200 |

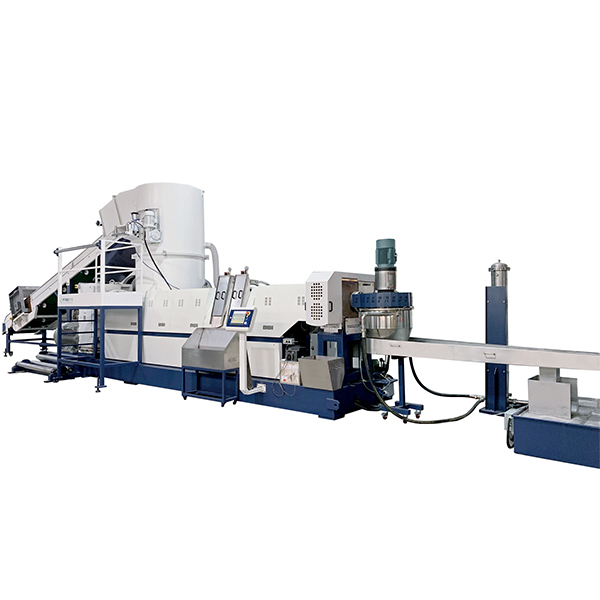

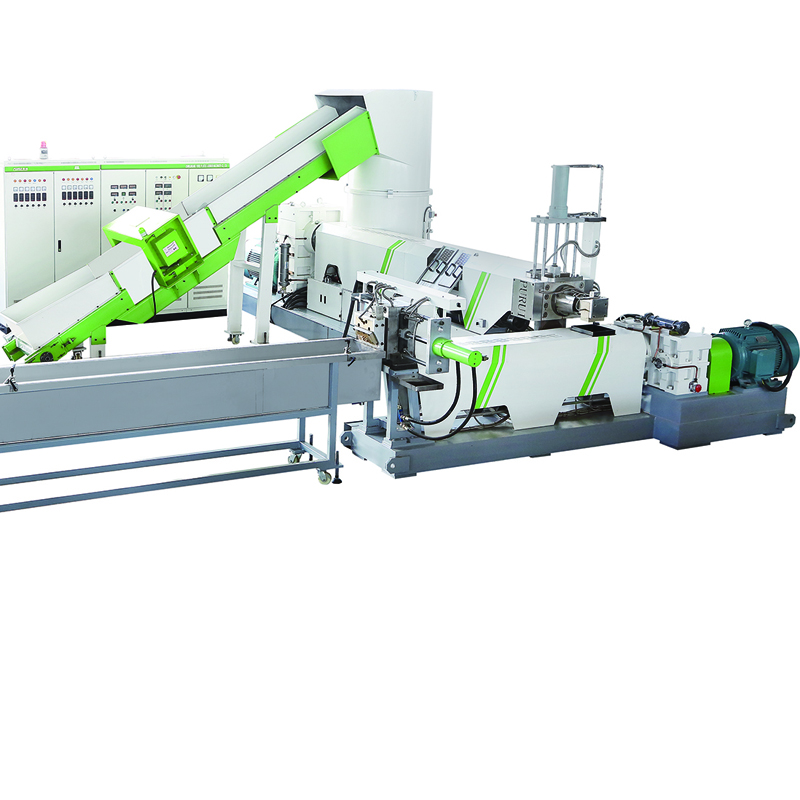

Machine Pictures:

Single screw extruder

Double stage recycling extruder

General Information:

| Model name | ML |

| output | Plastic pellets/granules/resins/plastic raw material |

| Machine parts | Belt conveyor, cutter compactor, main extruder, pelletizing unit, cooling system, silo, cabinet |

| Recycling material | PP/PE/LDPE/HDPE film, bag, fiber |

| Capacity range | 100kg/h to 1200kg/h |

| Feeding way | Conveyor, roll driving system |

| Screw diameter | 75mm to 200mm |

| Screw L/D | 26 to 33 |

| Screw raw material | 38CrMoAl or bimetallic |

| degassing | Natural degassing, vacuum degassing |

| Cutting type | Vertical pelletizing way, pull strip pelletizing |

| Cooling type | Water cool, air cool |

| voltage | Customized |

| Optional devices | Metal detector, water cooling system, feeding silo, vibration system |

| Delivery time | 40 to 60 days |

| Warranty time | 13 months |

| Technical supports | Machine layout, installation layout, engineer oversea service |

| Certificate | CE/ SGS/ TUV/CO |

Why choose us?

A.PURUI has professional manufacturer since 2006. we have our own technical design department. Each extruder get designed according to material feature.

B.Power saving with high output

C.Quality guaranty time is 12 months since the Bill of Lading date.

D.Delivery time: 40 work days to 60 days

E.Ship requested package

F.Machine installation is aboard available. It takes about 5 to 7 days with completing one time of installation. The assigned engineer(s) manage the machine user training, machine operation and commission.

Company Introduction:

Chengdu PuRui Polymer Engineering Co. Ltd is one of the leading manufacturers of plastic recycling machines, extruder, plastic granulator and related auxiliary equipment in China. Our plastic pelletizing system’s unique advantages are screw design, high output, good degassing and good filter effect. Our plastic washing line such as crusher with bearable resistance and sharp cutter, washing units, separating or sorting machine, drying system, and packaging system are of sound quality.

Product detail pictures:

Related Product Guide:

To create more value for customers is our business philosophy; customer growing is our working chase for China Wholesale Plastic Pelletizing Machine Factory Factories – Two stages plastics Film and fibers and bags Pelletizing machine – Purui , The product will supply to all over the world, such as: Greece, Liverpool, Ghana, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.