China Wholesale PPR extrusion machine Quotes – BOPP film granulating machine – Purui

China Wholesale PPR extrusion machine Quotes – BOPP film granulating machine – Purui Detail:

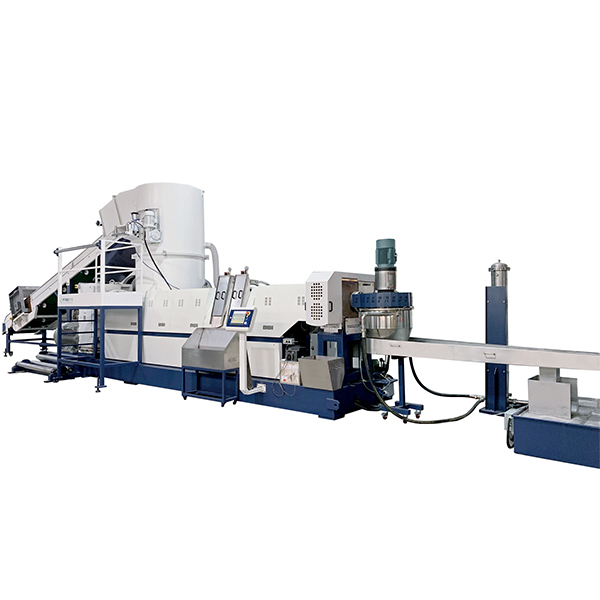

BOPP film granulating machine integrates the functions of crushing, compaction, plasticization and granulation, and is suitable for plastic recycling and granulation processes. The BOPP film granulator is a reliable and efficient solution for regranulation of plastic film, raffia fiber, filament, bag, woven bag and foam material. The final product produced by the Fangsheng BOPP film granulator is in the form of granules/granules, which can be directly put into the production line for film blowing, pipe extrusion and plastic injection, etc.

BOPP Film Granulating Machine Features:

1. The BOPP film granulating machine has good adaptability, almost all kinds of conventional plastic granulation can be adapted, and the energy consumption ratio of the equipment, the quality of the output product and the comprehensive competitive advantage are obvious. There is no common failure or bad phenomenon of ordinary granulator.

2. At the end of the screw barrel, a recycling granulator equipped with a double-column fast hydraulic non-stop screen changer can effectively filter out the dirt in the plastic melt.

3. The new particles after blow molding or injection can be used to make new plastic products. For example, plastic films, plastic bags, plastic bottles, plastic pallets, plastic boxes, plastic barrels, etc.

4. The automatic power distribution system is adopted to ensure the normal operation of the motor.

BOPP Films Recycling Granulating Machine Technical Parameter:

Normal:

| Model | SJ45 | SJ65 | SJ90 | SJ100 | SJ120 |

| Output(kg/h) | 10-60 | 100-150 | 180-250 | 250-350 | 300-600 |

High output,low consumption:

| Model | SJ150 | SJ160 | SJ180 | SJ200 |

| Output(kg/h) | 400-700 | 600-1000 | 1500-2000 | 2000-3000 |

BOPP Films Recycling Granulating Machine Working Procedure:

bopp film→belt conveyor→compactor→single screw extruder →hydraulic screen changer →pelletizing system →air transmission →silo storage

BOPP Film Granulating Equipment Detail:

Water-ring Die-face cutting system

Water-ring die-face/Strand cutting methods are usually adopted. In water-ring die-face cutting system, the rotary cutting blades will be pneumatically fit completely and closely to the die-face surface to ensure efficient cutting. Rotary speed of the blades is automatically adjusted by module system according to melt pressure at the die face.

video:

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for China Wholesale PPR extrusion machine Quotes – BOPP film granulating machine – Purui , The product will supply to all over the world, such as: UK, Portugal, Burundi, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, thorough meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!