China Wholesale Small Plastic Extruder Factories – SJ Series is single screw extruder for PP and HDPE rigid and squeezed materials – Purui

China Wholesale Small Plastic Extruder Factories – SJ Series is single screw extruder for PP and HDPE rigid and squeezed materials – Purui Detail:

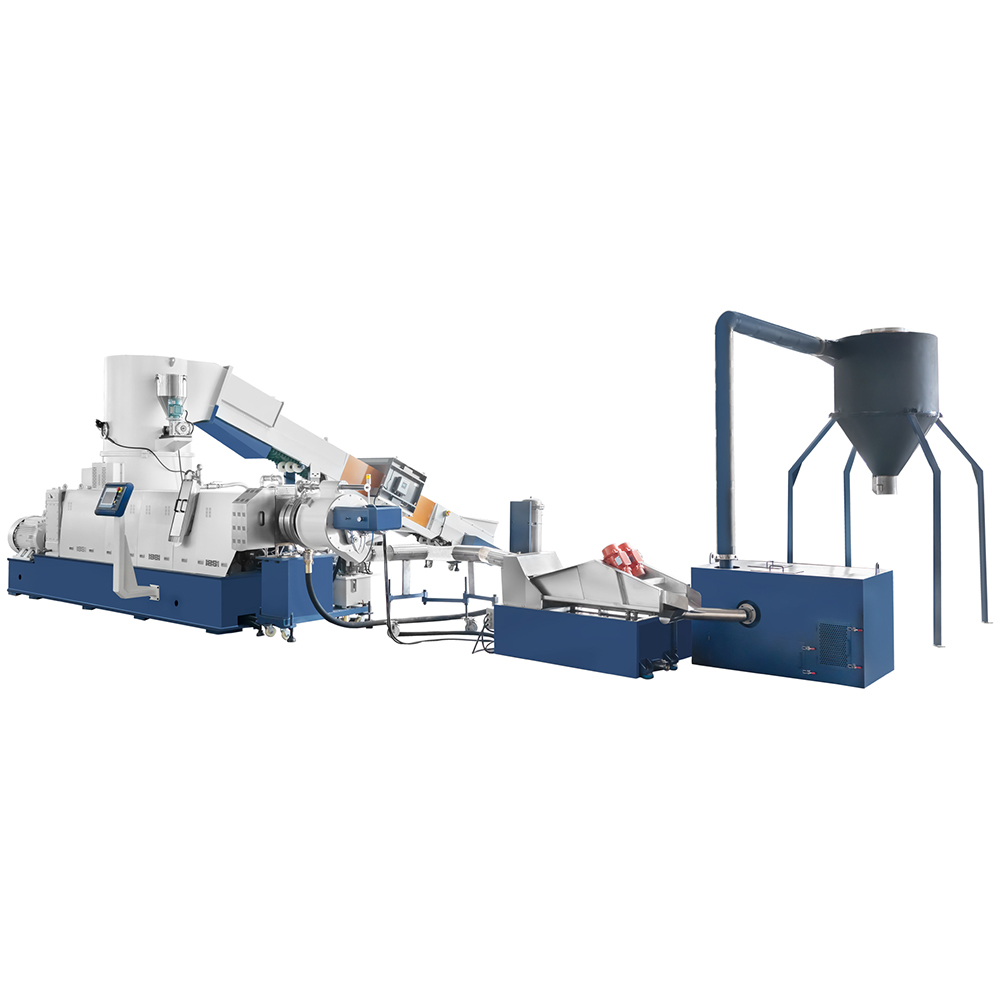

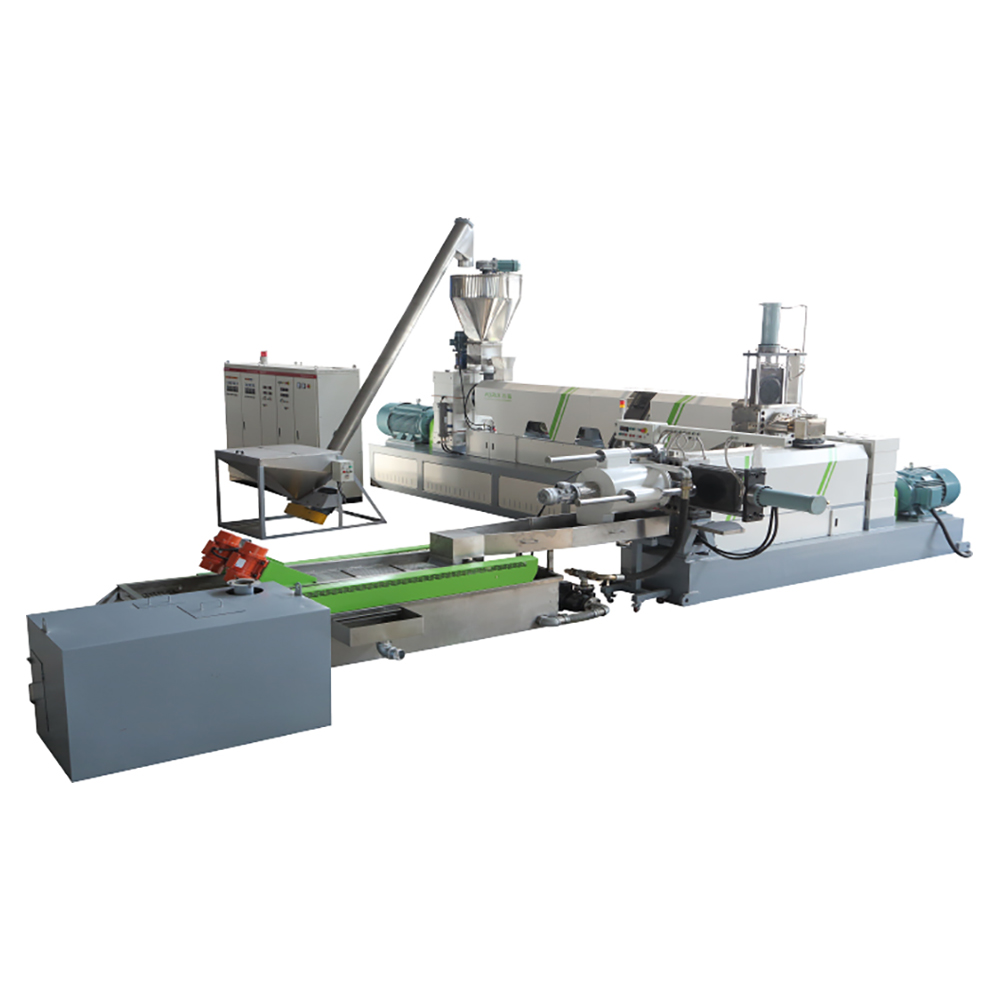

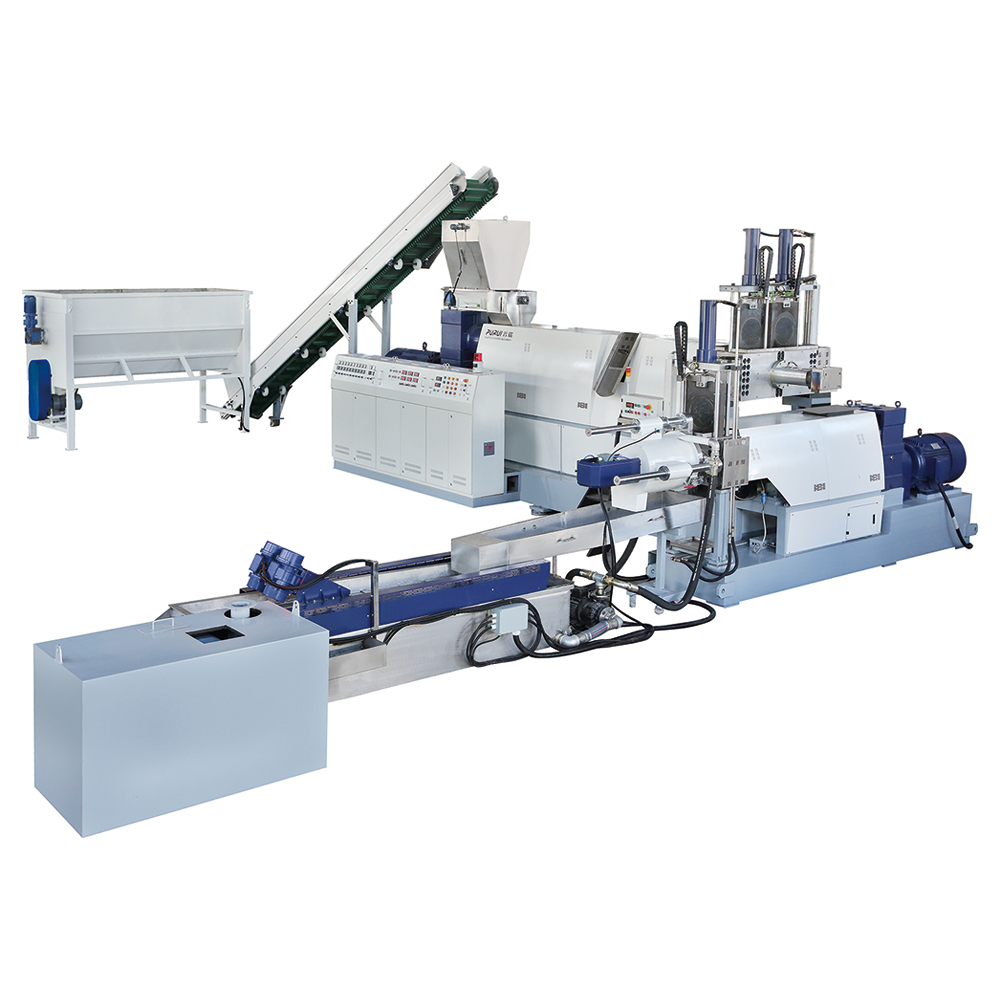

Single screw extruder recycling pelletizing system

SJ Series is single screw extruder recycling pelletizing system is a specialized and reliable system which suitable to the recycling and re- pelletizing. It combines function of plasticization and pelletizing to one step. Such as crushed PE, PP bottles and drums flakes and washed and squeesed dry PE films, also the ABS,PS,PP from the waste pallets, chairs, appliances etc. Capacity can be various from 100-1100kg/h.

Features equipment:

1.For the rigid plastics pelletizing

such as the The screw of the extruder is special designed for the different comparatively contaminated plastics with two times filtering. It can do the PP,PE,ABS and PC rigid plastics and the washed squeezed PP,PE films . The barrel can be wind cooling or water cooling. And the pelletizing type can be watering pelletizing, strand pelletizing and underwater pelletizing.

2.For the washed and squeesed drying PE PP films.

The moisture of the raw material need to be within 5-7%. It is with large silo with screw to automatically transfer the material into the belt, which will transfer the raw material into the extruder.

The machine is with two stages can effectively filter the impurities and easy to pelletize the raw material in the watering pelletizing system.

Case image:

According to customer request, we can make the pelletizing system to strand pelletizing or underwater pelletizing.

Characteristic:

With advanced design, high output, good plasticizing, low consumption, and spline gear transmission, it has the advantages such as low noise, stale running, good bearing capacity and long life.

Model for single stage extruder

| Model | SJ100 | SJ120 | SJ140 | SJ150 | SJ160 | SJ180 | SJ200 |

| Screw diameter | 100 | 120 | 140 | 150 | 160 | 180 | 200 |

| L/D | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 |

| Rotary speed | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 |

| Output(kg/h) | 250-350 | 300-400 | 500-600 | 600-800 | 800-1000 | 900-1200 | 1000-1500 |

Model for two stage extruder

| Model | SJ130/140 | SJ140/150 | SJ150/160 | SJ160/180 | SJ200/200 |

| Output(kg/h) | 500 | 600 | 800 | 1000 | 1000-1200 |

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for China Wholesale Small Plastic Extruder Factories – SJ Series is single screw extruder for PP and HDPE rigid and squeezed materials – Purui , The product will supply to all over the world, such as: Slovakia, Sweden, Frankfurt, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.