China Wholesale Waste Battery Recycle Plant Lead Acid Factory – Lithium-ion battery breaking and separation and recycling plant – Purui

China Wholesale Waste Battery Recycle Plant Lead Acid Factory – Lithium-ion battery breaking and separation and recycling plant – Purui Detail:

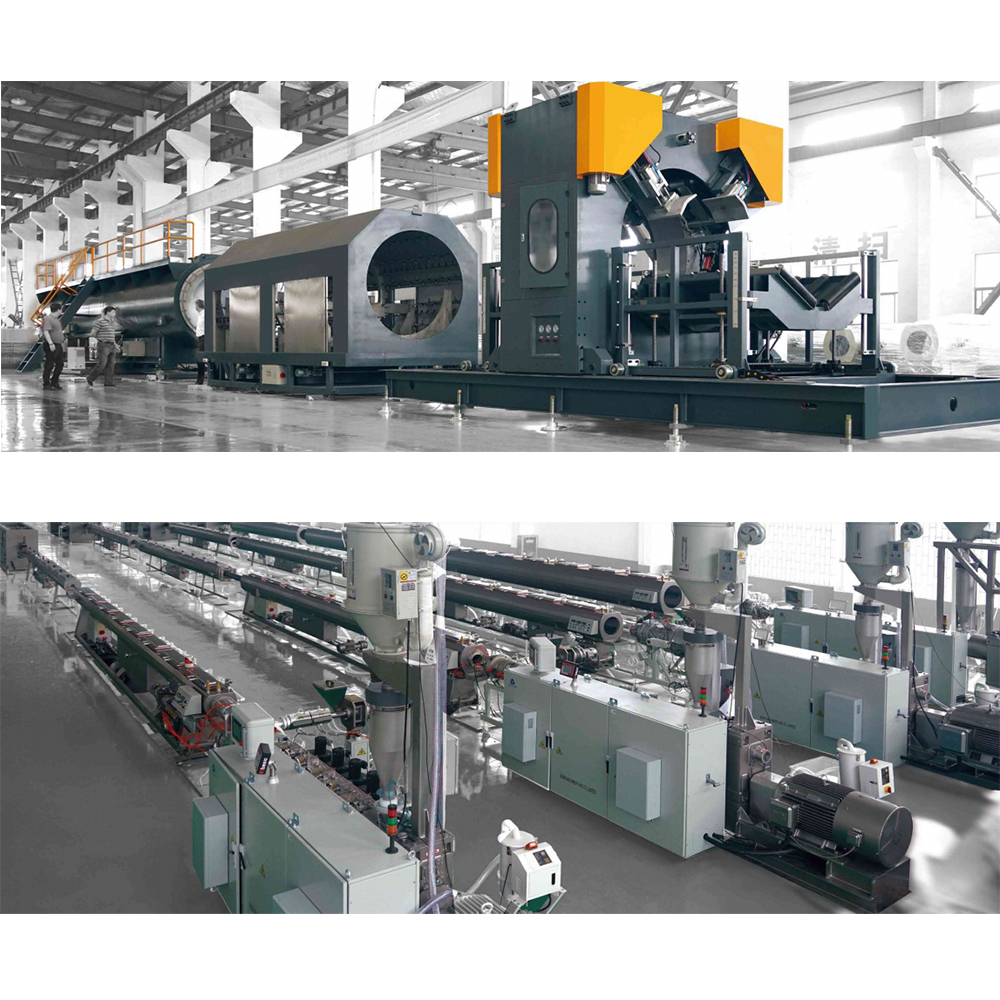

Waste Lithium-ion battery breaking and separation recycling system

The waste lithium-ion battery are mainly from the electrical vehicles, like the two wheels or the four wheels. The lithium battery generally has two types LiFePO4 as the anode and LiNi0.3Co0.3Mn0.3O2.

Our machine can process the lithium-ion LiFePO4 as the anode and LiNi0.3Co0.3Mn0.3O2. battery. The layout like the below:

- To break the batteries pack to separate and check the core is qualified or not. The battery pack will dispatch the shell, elements, aluminum and copper.

- The unqualified electric core will be crushed and separated. The crsher will be in the air device protection. The raw material will be anaerobic thermolysis. There will be a waste gas burner to make the exhausted air reach the discharged standard.

- The next steps is to separate with the air blow or the water power to separate the cathode and anode powder and the copper and aluminum and the pile head, and the shell scraps.

Waste lithium-ion battery pack breaking lines adopts manual work and high level of automation.

After breaking, crushing, separation and other continuous process, we could get the diaphragm, shell, copper foil, aluminum foil, anode & cathode powder and other products.

The process is based on market demand, resource regeneration and benefit maximization. Fully efficient recovery of single lithium batteries, leftover bits of materials can be achieved.

The all discharge is standard after the waste water and off-gas are treated.

The ecnomical output data:

| NO | Main products | Capacity or yield (%) | Recycling rate(%) |

| 1 | Cathode and anode | 47.47 | >97-98.5 |

| 2 | Copper | 11.76 | >98 |

| 3 | Aluminum | 3.91 | >98 |

| 4 | Electrolyte organic solvent | 12.73 | >97 |

| 5 | diaphragm | 5.92 | >84.5 |

| 6 | Plastic | 4.01 | >98 |

| 7 | Pile head and iron shell | 12.03 | >98 |

The technical parameter and consumption of the lithium-ion battery recycling line

| NO. | Item | Unit | Parameter |

| 1 | The capacity of lithium-ion recycling line | T/h | 0.2-4.0 |

| 2 | The handling the battery diagonal | mm | 420 |

| 3 | Total installation volume | kW | 1300 |

| 4 | Electricity consumption | kWH/t | 426 |

| 5 | Water consumption | M3/t | 0.125 |

| 6 | Waste water recycling use | % | >96 |

| 7 | Natural gas | M3/t | 26.7 |

| 8 | Auxiliary material consumption | USD/t | 2.5 |

| 9 | Directly processing cost | USD/t | 72 |

Features:

- With on-line oxygen content and temperature inspection, visual monitoring, PLC and charger etc, it intergrate the centrol interlock control. It reaches the CT4 explosion-proof. It is with high safty protection.

- As it is with electricity to crush, it can process the LiFePO4 as the anode and LiNi0.3Co0.3Mn0.3O2 battery and other types batteries with high compatibility. Apart from it, its structure shear tooth can process large capacity. Further more the final scraps are loose and become flakes which are easy to recycle. Finally the crusher is safe and solve the salt water long discharge time and water polution.

- The high yield of the cathod and anode powder. After the thermolysis and water power separation, the yield of cathod and anode power is about >98%(quality >98%), while the air blow separarion reaches 97%(quality >97%). The cathod powder aluminum content is <0.35%.

- The high yield recycling of the copper and aluminum. After the color sorter and photoelectric detection and sorting, the final quality of the copper and aluminum is about >99%.

- Environmental protection. The raw material in and out the machine is airtight. Also it is with anaerobic thermolysis, air and dust collecting system. We will strictly control the electrolyte and discharge. The air burner and purification use the specific technology wet defluorination. The execution HJ1186-2021 discharge standard.

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for China Wholesale Waste Battery Recycle Plant Lead Acid Factory – Lithium-ion battery breaking and separation and recycling plant – Purui , The product will supply to all over the world, such as: Istanbul, South Korea, Bulgaria, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!