Good quality China Plastic Pet Bottle Recycling Machine Price

With this motto in mind, we’ve got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for Good quality China Plastic Pet Bottle Recycling Machine Price, We welcome new and aged shoppers from all walks of daily life to call us for long term business associations and mutual accomplishment!

With this motto in mind, we’ve got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Pet Bottle Recycling Line, Plastic Recycling Machine Price, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

Product video:

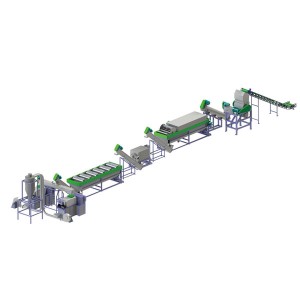

PP, PE film and PP woven bags recycling system

Layout:

1.Belt conveyer

2.Crusher

3.Horizontal friction washing

4.High speed friction washing

5.Floating tank

6.Screw loader

7.Dewatering maching

8.Screw loader

9.Floating washer

10.Screw loader

11.Plastic squeezer dryer

The main washing machines features:

A.Horizontal Friction Washing

It is designed to effectively remove the sand and label stick on the films. Will add water to wash.

B.High speed friction washing

It is designed to remove the sand the labels stick on the films. Will add water to wash.(picture)

C.Floating tank

It will float the raw material. And according to raw material situation, we may add the pneumatic valve to discharge the waste and sand. The design of the stainless steel chain to discharge waste to save the water.(picture)

D.Plastic dewatering machine

The dewatering machine removes dirty water, soil, and pulp after provious floating washing tank, so as to ensure the water in the subsequent washing tank is clean thus improve the cleaning performance.

The speed of the dewatering machine is 2000rpm running smoothly and low noise.(picture)

E.Plastic squeezer dryer

It will be used in the raw material drying in the washing system. Effectively remove the water and keep the moisture within 5%. Will largely improve the quality of the next plastic pelletizing processing. (Squeezer Picture)

Models:

| Model | NG300 | NG320 | NG350 |

| Output(kg/h) | 500 | 700 | 1000 |

| Raw material | PE films and yarn,PP films and yarn | PE films and yarn,PP films and yarn | PE films and yarn,PP films and yarn |

(to offer squeezer picture and raw material pictures)

With this motto in mind, we’ve got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for Good quality China Plastic Pet Bottle Recycling Machine Price, We welcome new and aged shoppers from all walks of daily life to call us for long term business associations and mutual accomplishment!

Good quality China Pet Bottle Recycling Line, Plastic Recycling Machine Price, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.