Hot Sale Good Service Plastic Recycling Washing Machine

Process introduction

This production line mainly recycles agricultural waste film (agricultural film/greenhouse film/tobacco film, etc.). At present, the agricultural waste film is processed in various parts of the country for centralized processing and recycling, and the degree of equipment automation is increased. PULIER has been involved in the manufacture of waste agricultural film processing and processing equipment for many years, and the equipment is constantly updated, improved and upgraded and solved many problems in the industry through our technologies. After the waste film is collected, it is pre-processed and cut or shredded so as to turn the large rolls of waste film into small pieces and then put it into the sand removal machine for sand removal treatment. Exorbitant sediment content will shorten the service life of the crusher and affect the cleaning effect. After sand removal, the film enters the crusher for fine crushing treatment. Water is added for crushing, which can play the role of preliminary cleaning. A friction washer is equipped at the bottom of the crusher, which can shake the sediment and dirty water on the material out. The spin-dried film enters the strong friction washer for friction cleaning. This section is filled with water for friction cleaning. Our company specially designs this machine for sand removal and cleaning of mulch film. The cleaning sediment is more than 99%. The cleaned film enters the floating washer and is then dug into the squeezing dryer for dehydration. Subsequent can be connected to a granulating line to make granules.

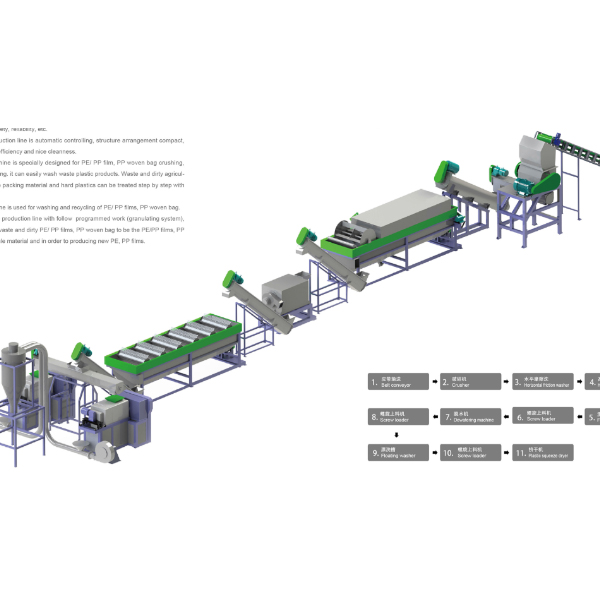

processing flow:

1. belt conveyor 2. crusher 3. screw loader 4. horizontal friction washer 5. high speed friction washer 6. screw loader 7. two tapper floating tank

8. horizontal friction washer 9. screw loader 10. water tank 11. horizontal spiral 12. screw loader 13. squeezer machine 14. silo

video please check as bellow links:

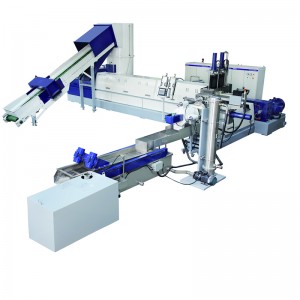

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.