-

Corner board plastic extrusion machine for pure PP and PE materials

Corner board plastic extrusion machine for pure PP and PE materials

New cooperated products designed for making the corner board profiles. The capacity is about 150kg/h. It can help customer to use the recycled or regrind PP and PE plastics to produce new plastics. It contains

1) Vacuum loader with drying hopper 1set;

2) 75 single screw extruder 1set;

3) 4.8meters vacuum shaping table 1set;

4) Haul-off and cutting machine whole type 1set;

5) Discharging stacker 1 set;

6) Main electric cabinet 1set.

7) Die mould

8)Single screw co-extruder

9) 5HP water chiller

10) Plastic crusher for recycling

The whole auxiliary machine are available.

-

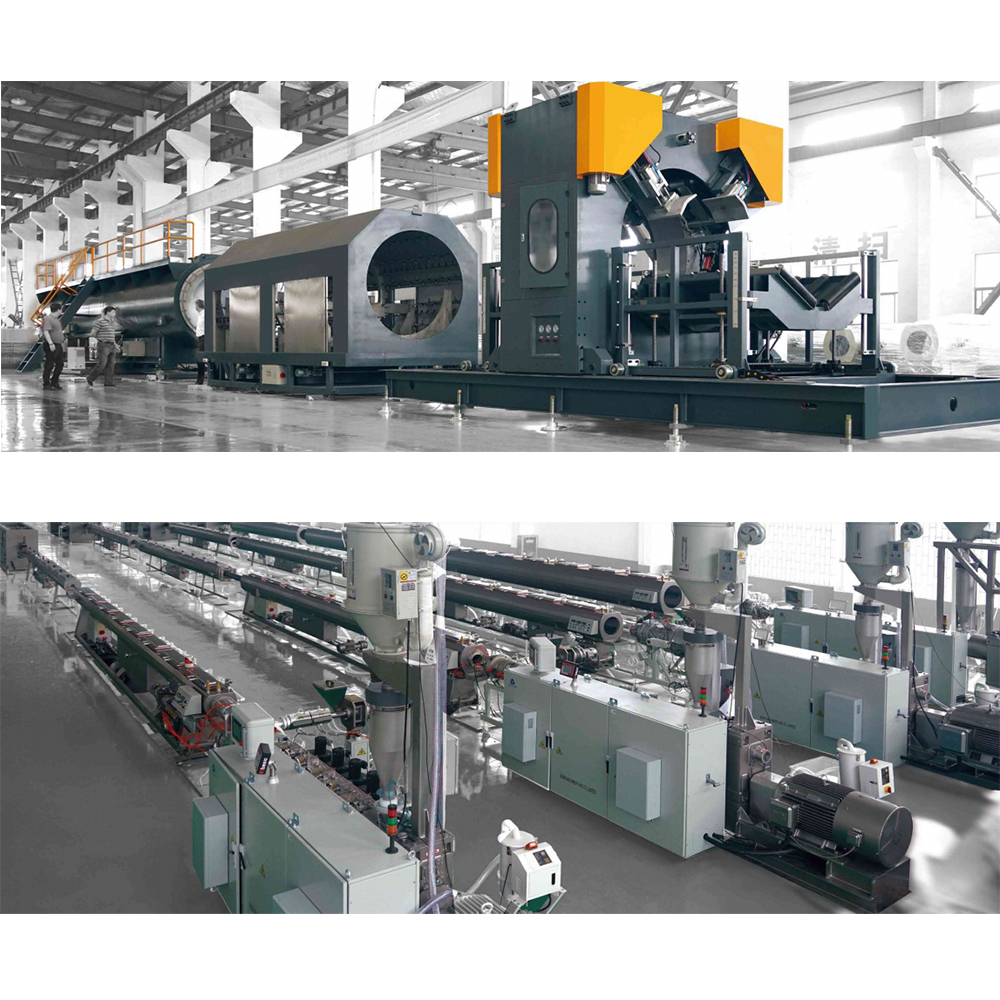

PE pipes extrusion machine

PE pipe extrusion machine

The main machine is for the PE pipe extrusion, capacity 400-450kg per hour. It is suitable for the PEpipe diameter 50-200mm.

Main extruder diameter: 60mm,

Dimension: 4200×1350×2600(mm)(Length*Width*height)

Whole machine weight: 3500(kg)

Heating type: ceramic+insulation cotton

Heating zone: 5(sections)

Heating power: 3.6(kw)×4 pieces+3.0(kw)×1piece

Temperature control: 50-300(℃)

We expanded our product zone. In the extrusion area, we have much experience. For more information, please feel free to contact us.

-

PVC pipe making machine

We have been worked with famous Chinese pipe and extruder companies to launch a series of extrusion equipment:

1.PPR,PP,PE pipe extruder

2.Multi-layer PPR tube extruder

3.PVC pipe extruder

4.PVC Exextruder

5.WPC Wood-Plastic Machine

6.PET sheet extruder

7.PC PMMA PSMS-chip extruderThe equipment is exported to 70 countries worldwide, with stable after-sales and strong technical team support, we can provide you with a full range of complete solutions and equipment.

PPR can be used for floor heating, residential and industrial central heating, industrial transportation (chemical liquids and gases), drinking water transportation, special applications, hot and cold water transportation.