plastic recycling machine for agriculture film

Experiences

With well strength of manufacturing ability, PURUI tech has been developed very good plastic recycling machinery and solution to all kinds of waste film recycling, lead acid battery recycling, PET bottle recycling. we delivers recycling solutions to customers not only on the all kinds of plastics, but also in electronic battery waste and lead acid battery

Let’s get started by the most difficult film as topic to talk about :

In case of film washing lines specifically dedicated to the recycling of pure agricultural film the key points of the recycling washing process are :

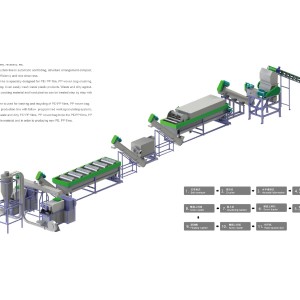

Belt conveyor +trommel + crusher/shredder+horizontal friction washer+high speed friction washer+ floating tank+spiral loader+squeezer+silo

(1) Remove the soils/mud out of any washing machine as quick as you can in order to prevent any sludge accumulated at the bottom of tank, so that the heavy, chunky and sticky sludge/mud can will not occupy the space inside of washing chamber, and further give expected performance of washing.

(2) The Friction wash machine can easily remove most of soil and mud through high speed centrifuge and impaction which has paddles on shaft. But be careful it might be jammed in the chamber of Friction Washer with improper design.

(3) Try to keep the folded and twisted film open-flat. Every one knows that pick up the coin from your pocket in jeans during laundry is very difficult. It is as difficult as washing film folded and twisted. A open-flat film can easily let contaminant come off during washing process, so that your extruder has no contaminant fed in, or increase the life time of screen changer.

Technical Details

|

Power Consumption in Comparison (kw/Hr) |

||||

|

|

500 Kg/Hr |

1.0 Ton/Hr |

1.5 Ton/Hr |

2.0 Ton/Hr |

|

In House Film |

190~230 |

220~250 |

240~265 |

300~330 |

|

A.G. Film |

295~330 |

350~420 |

375~450 |

420~475 |

|

Post-Consumer Film |

260~330 |

300~420 |

330~450 |

380~475 |

|

Water Consumption in Comparison |

|||

|

Film Type / Source |

In House |

A.G. |

Post-Consumer |

|

M3 / Hr |

3~5 |

15~20 |

8~12 |

Wearing & Maintenance Cost

PURUI Tech has always been placing the maximum effort in reducing wear of machinery parts. Reduction of costs associated with maintenance can be working with interchangeable pieces, durable design of housing, and perfect design of knife and its cutting movement. Moreover, thanks to additional pre-washing PURUI Tech properly balances the cost of the starting investments with wear and maintenance costs of the machineries that are particularly subject to the damaging action of the highly contaminated materials.

Drying specific modules

Drying must be carefully studied when treating the thinnest agricultural films, for which this step of the recycling process is particularly delicate. Specific modules have been designed by PURUI Tech to tackle this problem and carry out the drying process without damaging the produced film.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.