-

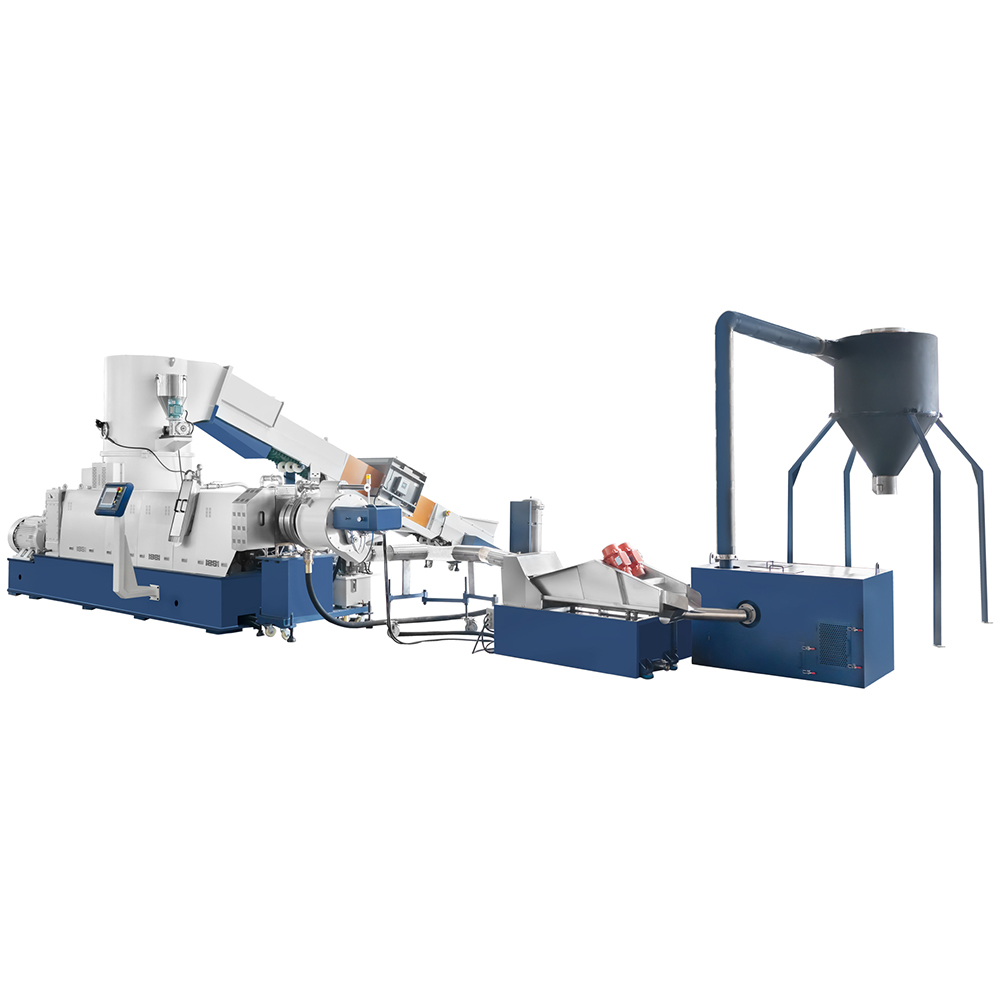

PP PE Film Recycling Extruder Machine with Shredding Agglomerator

With tiny metal get broken screw and barrel easily, many customer request for

Belt conveyor get inter-lock with shredding compactor. Once compactor inner temperature go high too much, and its ampere go increase too much, belt conveyor get stopped automatically.

Compactor cutter valve, which can monitoring the material feeding speed with avoiding melted compactor. That design do great help for balance cutting.

Double vacuum degassing system which can exhaust the gas and water at large extent.

Various hydraulic filtering system ensure large filtering screen for impurity. Stable pressure and fast screen changing speed.

Cutting system used according to material feature -

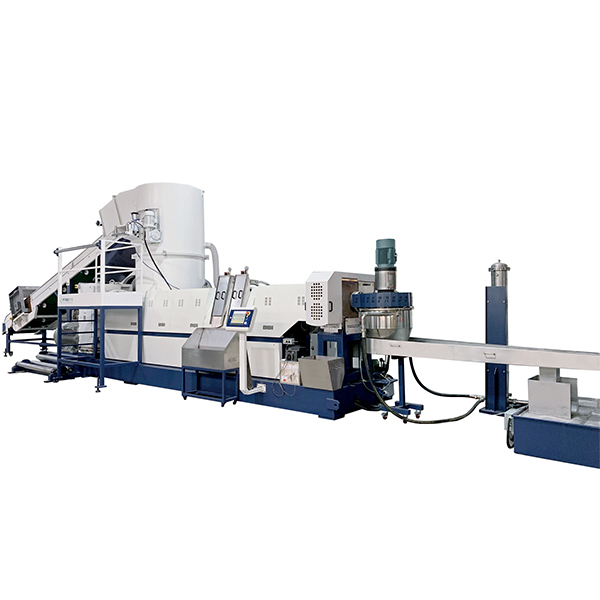

Two stages plastics Film and fibers and bags Pelletizing machine

Easy and automatic control and feed the soft plastics.

Belt conveyor get inter-lock with shredding compactor. Once compactor inner temperature go high too much, and its ampere go increase too much, belt conveyor get stopped automatically.

Compactor cutter valve, which can monitoring the material feeding speed avoiding melted compactor. That design do great help for balance cutting.

Double vacuum degassing system which can exhaust the gas and water vapor at large extent.

Various hydraulic filtering system ensure large filtering screen for impurity. Stable pressure and fast screen changing speed.

Cutting system used according to material feature -

Plastic Crusher for PP PE films and HDPE bottles

Plastic crusher machine for reduce the size of the plastics, such as the PE agriculture films, banana films and bags, PP films, PPwoven bags etc.

-

PP Jumbo bag Shredding Crushing Washing Drying Pelletizing Recycling Machine

PURUI Recycling Machine Process Material: Washing line can be used for PP woven bag, film and PE trash bag, film, packing material and some other loose material, agriculture film (1mm), industrial LDPE film with milk and powder, LDPE green- house film. Food packaging film, agriculture film, green house using film, film used in oil field, PP bag, PE film, PP woven bag, LDPE shrink film, multiple film, nature film or heavy printed film, cement bag, oily bag, dirty bag PURUI Recycling Mac... -

ML Model Single Screw Plastic Recycling Extruder with Cutter Compactor

With tiny metal get broken screw and barrel easily, many customer request for

Belt conveyor get inter-lock with shredding compactor. Once compactor inner temperature go high too much, and its ampere go increase too much, belt conveyor get stopped automatically.

Compactor cutter valve, which can monitoring the material feeding speed with avoiding melted compactor. That design do great help for balance cutting.

Double vacuum degassing system which can exhaust the gas and water at large extent.

Various hydraulic filtering system ensure large filtering screen for impurity. Stable pressure and fast screen changing speed.

Cutting system used according to material feature -

BOPP film granulating machine granulation machine

BOPP film granulation machine is designed to recyle the BOPP post indutrial films and sheets scraps.

-

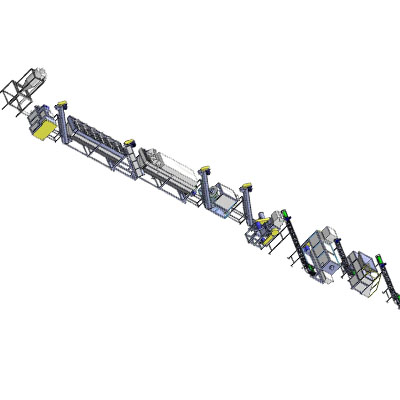

Low price for Plastic Recycling Machine /Pet Bottle Flakes Crushing and Washing Production Line

PET bottles washing line we accumulated much experience from the actual project for our customers from all over the world.

In India and homeland we have designed the complete lines for customers recycling the PET bottles. According to customers requirement, we can add or remove some specific machines to reach the target.

-

High definition Factory Wholesale Film Machine PP PE LDPE Plastic Line Pet Bottle Crushing Washing Drying Recycling with Manufacturer Price

PET bottles washing line we accumulated much experience from the actual project for our customers from all over the world.

In India and homeland we have designed the complete lines for customers recycling the PET bottles. According to customers requirement, we can add or remove some specific machines to reach the target.

-

New Vertical raw material transfer machine for plastics films washing friction washing and dewatering machine

New Vertical raw material transfer machine for plastics films washing friction washing and dewatering machine

Three function in one in the plastic PP PE films washing line

Friction washing

Dewatering machine

vertical raw material transfering machine

-

PP/HDPE /PS/ABS Plastic Waste Recycling Washing Machine

plastic washing machine for ABS/PS/PP home appliance housing, electronic waste, factory plastic,

In the field of HDPE/PP/PS/ABS/PC/PET recycling projects. Most of the materials come from urban and industrial collection sites,their sizes vary, and the composition of raw materials is different from country to country, even though the composition of HDPE/PP/PS/ABS/PC/PET in the same country is totally different.

-

plastic washing line for PET bottle/HDPE /industrial films/irrigation pipe

plastic washing line for PET bottle/HDPE /industrial films/irrigation pipe

with advanced PET bottle recycling and cleaning, ensuring the production of superior- quality recycled PET flakes. by leveraging our understanding of the unique attributes of PET bottle bales .

-

PP Jumbo Bag Crushing Washing Drying Pelletizing Recycling Machine

PP woven jumbo bags are always very dirty and with a lot of residue material. generally, the PP woven jumbo bag is too strong to crush/grind for common crusher machine/granulator,additionally, most of PP woven jumbo bags have a specially strong belt. That is why it is a headache problem for some small factory or company to resolve. we make and design an effective turnkey solutions to handle it easily according to our experience. First, using PP woven jumbo bag’s specially designed double shaft shredder machine to shred the woven bag into big pieces, and then we can use the common PP woven bag scraps washing line and also the PP woven jumbo bag pelletizing line to recycle them directly, finally, we can get the clean,dry PP woven bag scraps or PP repellets.