-

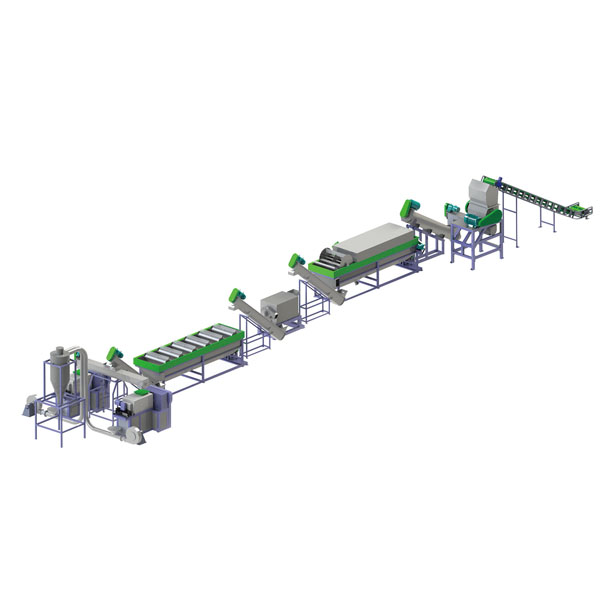

HDPE bottles recycling line with sorting, crusher and color sorting, hot washing and dry function

HDPE bottles washing line we accumulated much experience from the actual project for our customers from all over the world.

The HDPE bottles comes from detergent bottles, milk bottles etc in bales.Our washing line is complete with the bale opener, magnetic separator, prewasher, crusher, friction washing and floating tank and hot washing, label separator, color sorter and electric cabinet.

We have designed the complete lines for customers recycling the HDPE bottles in China and other countries. According to customers requirement, we can add or remove some specific machines to reach the target.

-

PP, PE film and PP woven bags recycling system china plastic washing machine

PP, PE film and PP woven bags recycling system china plastic washing machine production line is used to crush, wash, dewater and dry PP/PE film, PP woven bags which comes from post consumer or post industrial. The raw material can be the waste agriculture films, waste packing films etc.

Our plastic washing line features in the simple structure, easy operation, good performance, high capacity and low consumption etc. It will save much energy and labour.

After the raw materials washed well and dry well, it will get into the pelletizing line. The pelletizing line will process and pelletize the raw material to make it the nice plastic pellets for the next production. Either the material will be sold or to make the new films or bags.

-

Squeezer for PPPE film, the PP woven bags

As a machine to dry the cleaned PP LDPE,HDPE film, the PP woven bags, it provides great help to solve the moisture problem of cleaning materials.

The final moisture is within 3-5% for PE and PE materials. It plays a essential role in the plastic washing line. The end products can be directly to extruded pelletizing.

-

Preshredder for the PE agriculture films agriculture irrigating tape and PP woven bags

Preshredder for PE agriculture films

The function of the preshredder is to preshred the agriculture films like LDPE films etc. Even though it is with 70% sand or dust impurity for the mulch films, the preshredder could process without any problem. The greenhouse films can be also processed by the preshredder.

Picture for the mulch and greenhouse films

It features in the large capacity and stable working. The capacity can reach 1500-2000kg/h and 2000-3000kg/h. Below is the technical table for your reference.

-

Plastic single shaft shredder with pusher for shredding PP and PE films and rolls

The single shaft shredder work as a auxiliary machine for the plastic pelletizing, plastic washing line recycling system. Its function is to reduce the raw materials sizes. For example the plastics like PET fiber, PP woven bags ton bags and PP nonwoven bags, PE agriculture films processing, we need the single shaft to reduce theirs sizes.

-

The infrared preheating devolatilization system to remove the smells in raw materials

The infrared preheating devolatilization system adopts infrared radiation of the specified wavelength to heat the plastic raw material, such as the PA6/PA66, PBT, PC, PLA, PET and PETG,PP, PE etc.

After reaching the preset temperature, the materials will go to the vacuum module. The release of the colatile components in the cacuum environment is accelerated and desalination drying is cassried out.

The infrared preheating devolatilization system to remove the smell in raw materials

-

plastic recycling machine for agriculture film

With well strength of manufacturing ability, PURUI tech has been developed very good machinery and solution to all kinds of waste film recycling, lead acid battery recycling, PET bottle recycling. we delivers recycling solution to customer not only on machine combination, but also in electronic battery waste and lead acid battery

Let’s get started by the most difficult film as topic to talk about :In case of film washing lines specifically dedicated to the recycling of pure agricultural film the key points of the recycling washing process are :

Belt conveyor +trommel + crusher/shredder+horizontal friction washer+high speed friction washer+ floating tank+spiral loader+squeezer+silo

-

A High-Performance Solution for Drying Film or PP Woven Bags-Squeezers

high capacity of squeezer machine for PE/PP film, PP woven bags, high capacity and lower consumption.

-

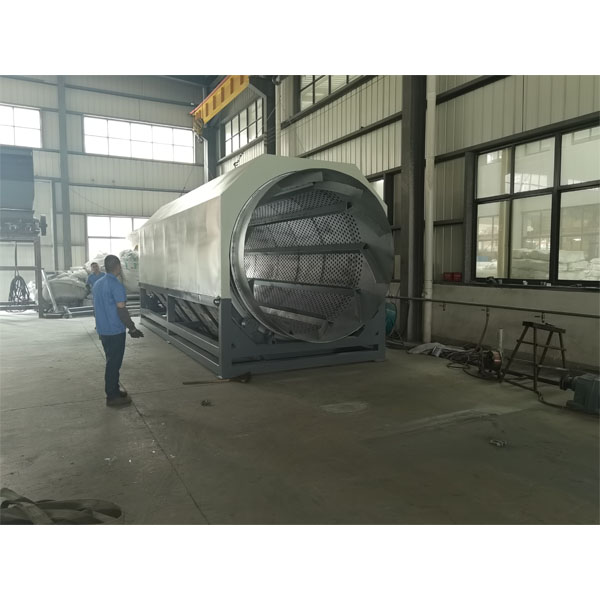

Trommels Can be integrated to new or existing plants For waste management and recycling facilities

Our Trommels are designed, manufactured and installed for all applications and can be integrated into new or existing plant

The Trommel – Features & Benefits

Specially designed composite chassis, engineered from Universal Beam

Drum diameter to suit customer requirements

Total screening length ranging from 4m- 12m

Trommel drum is manufactured from heavy duty plate steel with parallel flange channel for extra strength

Bolt in heavy duty 6-12mm punch plate for easy changing with staggered patterned aperture for increased strength (aperture to customer requirements)

variable speed control

SKF bearings throughout

Full guards with emergency stops

Various lifting bars on drum to provide aggressive screening action

Options

Low level feeder via incline conveyor to trommel

-

shredder machine for waste plastic PP big bags/woven bags/PE film

Single and double shaft shredders are both commonly used for shredding waste plastic.

Single shaft shredders have one rotor with blades that rotate at high speeds to shred the plastic into smaller pieces. They are often used for softer materials like plastic film, while heavier-duty models can handle thicker plastic items such as pipes and containers.

Double shaft shredders have two interlocking rotors that work together to shred the plastic. The two rotors rotate at different speeds and the blades are positioned in such a way that the plastic is continuously torn and shredded until it reaches the desired size. Double shaft shredders are typically used for tougher materials like plastic blocks and heavy-duty containers.

Both types of shredders have their own advantages and disadvantages, so the choice between them depends on the specific needs of the application. For instance, single shaft shredders tend to be more compact and require less power, while double shaft shredders are more efficient at shredding tougher materials and can handle larger volumes of waste.

-

Post-Agriculture Film Recycle Washing Plant

Post-Agriculture PE Film Washing Line Plastic film cutting, washing, recycling machine with high output and excellent clean ability (500kg/h to 6500kg/h) The whole plastic recycling line is used to crush, wash, dewater and dry the PP/PE film, PP woven bag Processing material: This washing line can be used for the PP woven bag, film and PE trash bag, film, packaging material and some other loose material, agriculture film (1mm), industrial LDPE film with milk and powder, LDPE green house film...