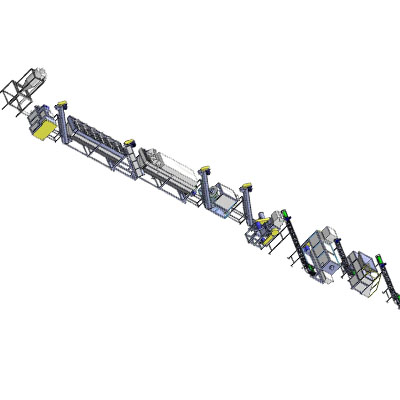

PP Jumbo Bag Crushing Washing Drying Pelletizing Recycling Machine

waste PP woven bag crushing washing recycling machine consists of : belt conveyor, crusher (grinder), high speed friction washer, floating washer, dewatering machine, squeezer machine, and other components. details please check this video.

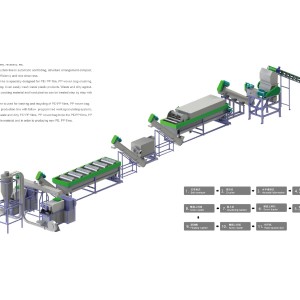

processing details:

| NO | Process | Machine | Description |

| 1 | Send the woven bag to the wet crusher machine | Conveyor with Metal Detector(Optional) | It separates impurities such as metals in the woven bag, Sends the materials to the wet crusher machine |

| 2 | Cuts the pp woven bag into small pieces size | Wet Crusher Machine | A wet crusher cuts the PP woven bag into small pieces approximately 10-20mm in size and moves onto the next piece of equipment. |

| 3 | Send the woven bag to the Floating Washing machine | Screw Feeder | Put the woven bag into the Hot washer to clean |

| 4 | The first time Floating wash the woven bag | Floating Washing Tank | As the woven bag enters the friction washer, the woven bag rubs against each other at high speeds getting rid of hard-to-remove contamination. |

| 5 | Feeding woven bag scraps to friction washer | Screw Feeder | Put the woven bag into the High-speed Friction Washer to clean |

| 6 | Separate the contamination from the plastic woven bag | High-Speed Friction Washing Machine | After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect. |

| 7 | The second time Floating wash the woven bag | Floating Washing Tank | It is used in cleaning plastic woven bags, making the film cleaner. |

| 8 | Dry the plastic woven bag | Horizontal Dewatering Machine | The dewatering machine uses centrifugal force to spin water moisture off the plastic woven bag. |

| 9 | Hot air to dry the woven bag | Squeezer machine | Squeezing the materials take the humidity away from the clean material. |

| 10 | Storage dry pieces of woven bag | Storage silo | A storage tank for the clean, dry pieces of woven bag. |

| 11 | make the plastic woven bag into granules(Optional) | Pelletizer / Extruder | We offer both single-screw extruders and twin-screw extruders. Based on your requirements, we offer both one-stage and double-stage pelletizing setups where granules can be formed using a granulator or water-ring cutting. |

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.