-

lithium ion battery recycling equipment

An e-waste recycling machine is a device that is designed to recycle electronic waste. E-waste recycling machines are typically used to recycle old electronics, such as computers, televisions, and mobile phones, which would otherwise be discarded and end up in landfills or incinerated.

The process of e-waste recycling typically involves several steps, including disassembly, sorting, and processing. E-waste recycling machines are designed to automate many of these steps, making the process more efficient and cost-effective.

Some e-waste recycling machines use physical methods, such as shredding and grinding, to break down electronic waste into smaller pieces. Other machines use chemical processes, such as acid leaching, to extract valuable materials like gold, silver, and copper from electronic waste.

E-waste recycling machines are becoming increasingly important as the amount of electronic waste generated around the world continues to grow. By recycling electronic waste, we can reduce the amount of waste that ends up in landfills, conserve natural resources, and reduce the environmental impact of electronic devices.

-

shredder machine for waste plastic PP big bags/woven bags/PE film

Single and double shaft shredders are both commonly used for shredding waste plastic.

Single shaft shredders have one rotor with blades that rotate at high speeds to shred the plastic into smaller pieces. They are often used for softer materials like plastic film, while heavier-duty models can handle thicker plastic items such as pipes and containers.

Double shaft shredders have two interlocking rotors that work together to shred the plastic. The two rotors rotate at different speeds and the blades are positioned in such a way that the plastic is continuously torn and shredded until it reaches the desired size. Double shaft shredders are typically used for tougher materials like plastic blocks and heavy-duty containers.

Both types of shredders have their own advantages and disadvantages, so the choice between them depends on the specific needs of the application. For instance, single shaft shredders tend to be more compact and require less power, while double shaft shredders are more efficient at shredding tougher materials and can handle larger volumes of waste.

-

Lead acid battery recycling machine and sorting machine

video Introduce The working principle of the waste lead storage battery crushing and separating system is that the storage battery is crushed by a crusher, the crushed fragments are cleaned by a vibrating screen, lead mud is washed away, the cleaned fragments enter a hydraulic separator and are separated by utilizing the characteristics of different specific gravity of materials, and the separated battery plastic fragments and a lead grid pass through screw conveyor output systems from differ... -

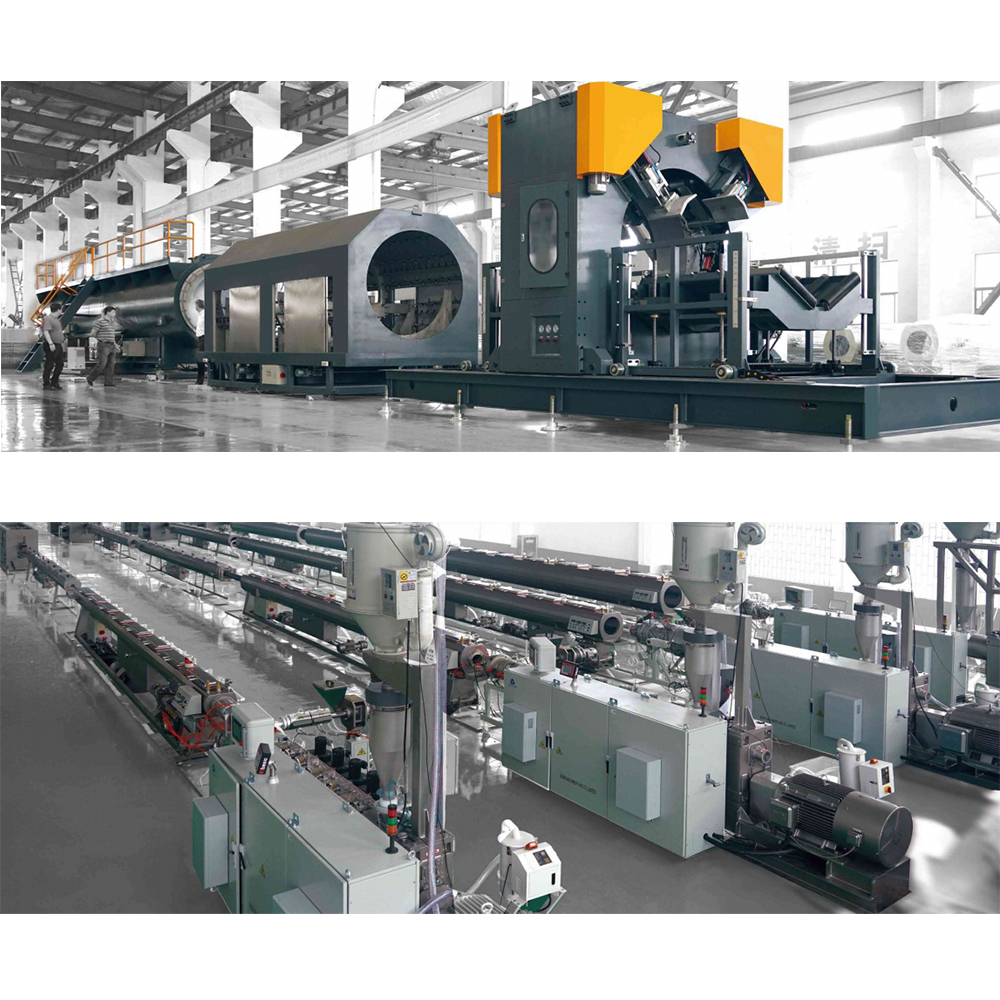

PVC pipe making machine

We have been worked with famous Chinese pipe and extruder companies to launch a series of extrusion equipment:

1.PPR,PP,PE pipe extruder

2.Multi-layer PPR tube extruder

3.PVC pipe extruder

4.PVC Exextruder

5.WPC Wood-Plastic Machine

6.PET sheet extruder

7.PC PMMA PSMS-chip extruderThe equipment is exported to 70 countries worldwide, with stable after-sales and strong technical team support, we can provide you with a full range of complete solutions and equipment.

PPR can be used for floor heating, residential and industrial central heating, industrial transportation (chemical liquids and gases), drinking water transportation, special applications, hot and cold water transportation.

-

TSSK series is Co-rotating double/Twin screw extruder

TSSK series is Co-rotating double/Twin screw extruder, it is our most popular twin screw extruder. it have excellent mixing performance, good self-cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of materials.

-

Lithium-ion battery breaking and separation and recycling plant

The waste lithium-ion battery are mainly from the electrical vehicles, like the two wheels or the four wheels. The lithium battery generally has two types LiFePO4 as the anode and LiNi0.3Co0.3Mn0.3O2.

Our machine can process the lithium-ion LiFePO4 as the anode and LiNi0.3Co0.3Mn0.3O2. battery. The layout like the below:

- To break the batteries pack to separate and check the core is qualified or not. The battery pack will dispatch the shell, elements, aluminum and copper.

- The unqualified electric core will be crushed and separated. The crsher will be in the air device protection. The raw material will be anaerobic thermolysis. There will be a waste gas burner to make the exhausted air reach the discharged standard.

- The next steps is to separate with the air blow or the water power to separate the cathode and anode powder and the copper and aluminum and the pile head, and the shell scraps.

-

SJ type pelletizing machine for PP PE rigid plastics and squeezed plastics

SJ type pelletizing machine for PP and PE rigid plastics and squeezed plastics after plastic squeezer. It performs well in recycling the HDPE bottle flakes from the detergent bottles, HDPE milk bottles, etc.

-

Post-Agriculture Film Recycle Washing Plant

Post-Agriculture PE Film Washing Line Plastic film cutting, washing, recycling machine with high output and excellent clean ability (500kg/h to 6500kg/h) The whole plastic recycling line is used to crush, wash, dewater and dry the PP/PE film, PP woven bag Processing material: This washing line can be used for the PP woven bag, film and PE trash bag, film, packaging material and some other loose material, agriculture film (1mm), industrial LDPE film with milk and powder, LDPE green house film... -

SJ Series is single screw extruder for PP and HDPE rigid and squeezed materials

The single screw extruders are developed for a very basic form of extruder that simply melts and forms the material. Due to their low cost, simple designs, ruggedness, and reliability, single screw extrusion machines are one of the most popular extruding machines and widely used for all kinds of plastics recycling.

-

PET flake granulation machine

CT series is single screw extruder for recycle PET flakes. PET flakes granulation line design as combination of single screw extruder and high efficient vacuum system streamlines the whole process, yet keeps the final pellets in good quality.