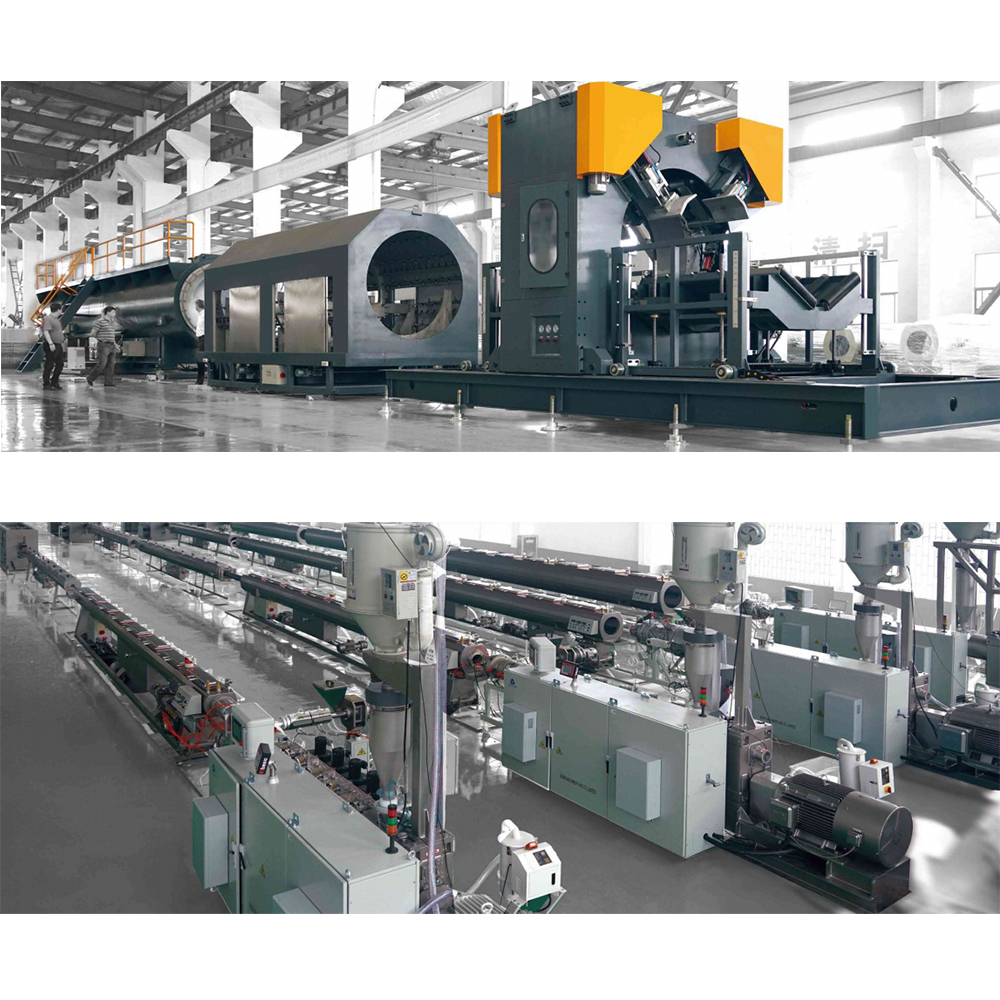

PVC pipe making machine

Product Video:

1.PPR can be used for floor heating, residential and industrial central heating, industrial transportation (chemical liquids and gases), drinking water transportation, special applications, hot and cold water transportation.

Advantages:

- The extruder screw adopts L/D=38, double mixing head, separated structure, making the melt material plastic by 100% before entering the touch head. Open spiral groove at feed end to increase yield by 30%

- The mold head adopts spiral design without hysteresis phenomenon, which can greatly improve the quality of pipe materials. Fixed sleeve is a special disc design, the guarantee of high speed extrusion pipe

- Double vacuum box is completely independent control and operates as convenient as single line

- The dual tractor is completely independent control, as convenient for operation as a single line, with the upper track limit device, which can ensure the roundness of the pipe.

- Double cutter is chip-free cutting with completely independent control and easy to operate.

Main parameter:

| Model | 60/38 | 75/38 | 90/38 | 120/38 | |

| Application | Raw material | Maximum capacity | |||

| Water supply and gas | PE | 500 | 650 | 1100 | 1350 |

| Antistatic coating | PR-RT | 400 | 600 | 1000 | 1200 |

| Pipe fitting | PPR | 350 | 520 | 800 | 1100 |

| Drainage and Sewage | PP | 350 | 520 | 800 | 1000 |

2.PVC pipe

Application: pressure water pipe, sewage pipe system, drainage pipe system, electrical appliances and telecommunications engineering pipeline

Main technical parameters

|

Pipe diameter |

16-40double pipes |

16-63double pipes |

50-160 |

75-250 |

110-315 |

160-450 |

315-630 |

|

Conical twins crew extruder |

SJZ51/105 |

SJZ65/132 |

SJZ65/132 |

SJZ65/132 |

SJZ80/1156 |

SJZ80/156 |

SJZ92/188 |

|

Main motor(kW) |

18.5AC |

37AC |

37AC |

37AC |

55AC |

55AC |

110AC |

|

Maximum capacity |

100-120 |

280-350 |

280-350 |

280-350 |

400-550 |

400-550 |

700-800 |

PE pipemaking machine 1

PE pipe making machine 2

PVC pipe making machine

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

FAQ for PVC pipe line

Please answer below questions to offer providing

1.Pipe performance

□UPVC pipe □ SPVC pipe □ CPVC pipe □ Others

2.Application:

Final products will be used for:

□ Water supply □ Water drainage or sewage □ Cable □ Others

3.Max. Caco3 percentage (PHR)

□ Less than 10 PHR □ 20-50PHR □ 50-100PHR □ More than 100PHR

4.Layer structure

□ Monolayer

□ Two layers

□ Three layers

Please help to fill this pipe below:

|

Layer |

Material |

Proportion |

Note |

|

A |

% |

||

|

B |

% |

||

|

C |

% |

5.Pipe tolerance thickness

|

Pipe Dia. |

Standand thickness |

Tolerance |

Note |

6.Output

□ Extrusion weight: ____KGH * _____Working hours per day * ______Working days per year

□ Extrusion speed: ____m/min

7.Business Scope

|

Index |

BEIER |

Buyer |

| Warehouse | × | 1. Length*Width*Height: ____M*____M*_____MPillar positions, providing CAD drawing to BEIER

2. Ground floor flatness 3. Altitude of site: □ up to 1000m(NN) ▽ higher than 1000m(NN), i.e. ………………..m(NN) |

| Water flow | × | 1. Underground water channel or PVC pipelines & pumps? |

| Folk lift | × | 1. loading capacity 3.5-5Ton |

| Electricity supply | Electric cabinet | 1. Do you have enough capacity transformer to load all motors & office unities?2. Cable/wires from transformer to electric cabinet

3. Cable/wires from electric cabinet to each motor 4. Voltage: Drive cabinet supply: 3 Phase _____V ____Hz Control cabinet supply: ______V _____Hz Voltage fluctuation: □ up to max ± 10% ○ up to max ± 15% ▽ over ± 15%, |

8. Infrastructure Status

Climatic condition Ambient temperature max. relative humidity

| □ moderate | up to 35 ℃ | 70% |

| ▽ dry/warm | up to 40 ℃ | 40% |

| ▽ dry/hot | over to 40 ℃, i.e. ……………….. ℃ | 40% |

| ▽ humid/warm | up to 40 ℃ | 90% |

| ▽ humid/hot | over to 40 ℃, i.e. ……………….. ℃ | 90% |

FAQ for HDPE pipe line

Please answer below questions to offer providing

1.Raw Material

□ Borouge □ Sabic □ Sinopec □ Others

2.Color stripe lines

□ one line □ two lines □ four lines □ six lines □ eight lines

3.Layer structure

□ Monolayer

□ Two layers

□ Three layers

□ Four layers

Please help to fill this pipe below:

|

Layer |

Material |

Proportion |

Note |

|

A |

% |

||

|

B |

% |

||

|

C |

% |

||

|

D |

% |

4.Pipe tolerance thickness

|

Pipe Dia. |

Standand thickness |

Tolerance |

Note |

5.Output

□ Extrusion weight: ____KGH * _____Working hours per day * ______Working days per year

□ Extrusion speed: ____m/min

6.Application:

Final products will be used for:

□water supply □ water drainage or sewage □ Gas pipe □ Irrigation pipe

7.Business Scope

|

Index |

PURUI |

Buyer |

| Warehouse | × | 1. Length*Width*Height: ____M*____M*_____MPillar positions, providing CAD drawing to BEIER

2. Ground floor flatness 3. Altitude of site: □ up to 1000m(NN) ▽ higher than 1000m(NN), i.e. ………………..m(NN) |

| Water flow | × | 1. Underground water channel or PVC pipelines & pumps? |

| Folk lift | × | 1. loading capacity 3.5-5Ton |

| Electricity supply | Electric cabinet | 1. Do you have enough capacity transformer to load all motors & office unities?2. Cable/wires from transformer to electric cabinet

3. Cable/wires from electric cabinet to each motor 4. Voltage: Drive cabinet supply: 3 Phase _____V ____Hz Control cabinet supply: ______V _____Hz Voltage fluctuation: □ up to max ± 10% ○ up to max ± 15% ▽ over ± 15%, |

8. Infrastructure Status

Climatic condition Ambient temperature max. relative humidity

| □ moderate | up to 35 ℃ | 70% |

| ▽ dry/warm | up to 40 ℃ | 40% |

| ▽ dry/hot | over to 40 ℃, i.e. ……………….. ℃ | 40% |

| ▽ humid/warm | up to 40 ℃ | 90% |

| ▽ humid/hot | over to 40 ℃, i.e. ……………….. ℃ | 90% |