Wholesale Discount Plastic Grinding Milling Granulators

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Wholesale Discount Plastic Grinding Milling Granulators, We warmly welcome all intrigued shoppers to make contact with us for more data.

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for China Plastic Granulators and Granulator, Facing fierce global market competition, we’ve got launched the brand building strategy and updated the spirit of “human-oriented and faithful service”, with an aim to gain global recognition and sustainable development.

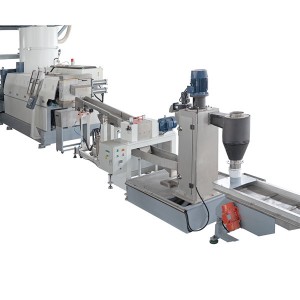

PET fiber fabrics pelletizing and recycling machine

It can recycle the most of the soft plastics and some rigid plastics. The soft material contains wholes rolls and crushed PET fibers and films, PET fabrics, LLDPE, LDPE,HDPE,PP,BOPP,CPP from post industrial or post consumer.

Considering the materials characteristics, for some post industrial material we may prefer the single stages pelletizing system. For example the the BOPP films, PET fibers from water jet weaving selvedges, POY discards and DTY discards etc. Considering the regrind pellets will be used for making the new films or fibers, we improve the filtering system. Finally we add two filters on the single screw. In the middel we add one melt pump to increase melt pressure ensure the melted raw material get into the second filter for fine filtering. It will not only increase the pellets quality but also increase the pellets quality.

Apart from the filtering system, we make some improvement on the cutter compactor to add one dehumifying system, it will largely decrease the moisture content of the raw materials.

Finally we will have the under water strand pelletizing to make the strand easy to feed into the pelletizer. It will save the manual work comparing the dry strand pelletizing.

|

Model |

ML85 |

ML100 |

ML130 |

ML160 |

ML180 |

|

Output(kg/h) |

120-200 |

200-400 |

400-650 |

600-1000 |

800-1200 |

|

Model |

ML85B |

ML100B |

ML130B |

ML160B |

ML180B |

|

Output(kg/h) |

200-350 |

400-550 |

600-800 |

800-1200 |

1000-1500 |

We have been in the plastic recycling machine for more than 15 years. Exporting to more than 70 countries, with good after sale service and reputation. We will continue to serve our customers and offer the best quality machines.

For any enquiry, please contact us freely.

Contact person:Aileen.he@puruien.com

Email: aileen.he@puruien.com

Mobile:0086 15602292676(whatsapp and wechat)

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Wholesale Discount Plastic Grinding Milling Granulators, We warmly welcome all intrigued shoppers to make contact with us for more data.

Wholesale Discount China Plastic Granulators and Granulator, Facing fierce global market competition, we’ve got launched the brand building strategy and updated the spirit of “human-oriented and faithful service”, with an aim to gain global recognition and sustainable development.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.