solution

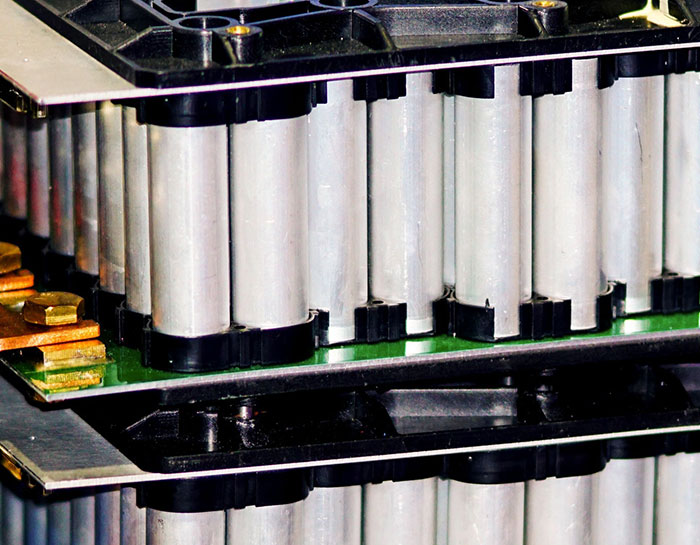

what we could do to make the best of the waste plastic and battery?

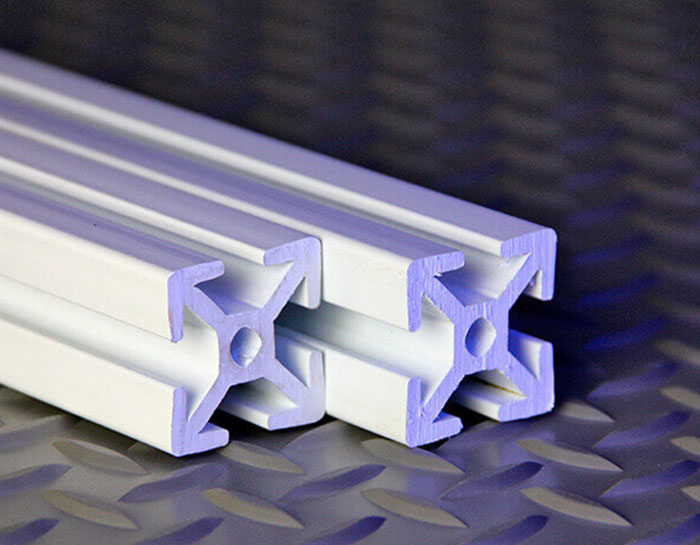

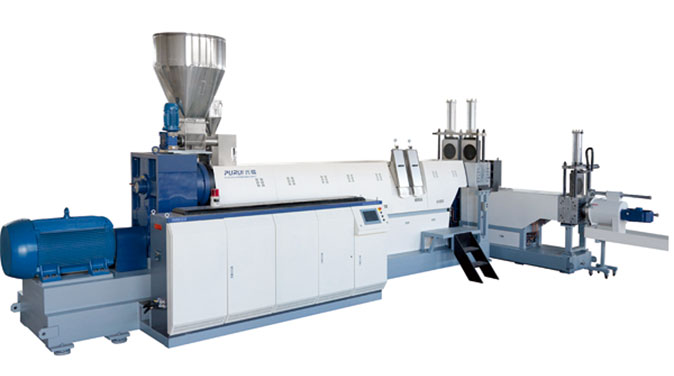

our features in the plastic recycling machine

To India, Russia, Germany, France, Spain, South Africa, Sudan, USA, Colombia, Brazil, Japan, south Korea, Malaysia, Indonesia, Austrilia, our recycling and pelletizing system bas been exported .

We are a professional plastic recycling machine supplier with twenty years of production experience and support customized products. Please click the button below to get a free quote.

contact uslatest news

-

CHINAPLAS 2025 Booth NO.: 6L61

25/03/17Dear partners: We sincerely invite you to visit CHINAPLAS 2025 (April 15-18, 2025, Shenzhen World Exhibition & Convention Center) to see our latest plastic recycling machinery solutions in the Recycling Technology Zone (Booth No. 6L61). As Asia’s largest and most influential rubber and ...

-

Plastico Brasil 2025, Both NO.GH160

25/03/17Plastico Brasil 2025, Both NO.GH160 Welcome to our booth in Plastico Brasil 2025. Both No.:GH160 Time: 24-28th March Address: estande D 130 Sao Paulo We will waiting for your visiting and discuss more detail on the plastic recycling projects. We are specialized in the plastic recycling mach...

-

RePlast Eurasia fair in Istanbul Turkey

24/04/17As a leading company in the plastic recycling industry for over 18 years, we continuously strive to innovate and improve our pre-sales and after-sales services. Our mature plastic recycling technology enables our products to be exported to 50 countries around the world, establishing a strong pre...

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top